9. Maintenance

🔧 Tools Required

• Torque wrench (0-100 Nm range)

• Socket set (M12 hex nuts)

• M8 ring bolt (for basket extraction)

• Soft brushes (no metal bristles on PTFE)

• Cleaning materials (lint-free cloth, approved solvent)

• Digital caliper (gap measurement)

• Pliers (for round cord installation)

• Grease (approved for PFA contact)

📋 Recommended Spare Parts

• Complete strainer basket assembly (size-specific: DN 25, 40, 50, 80, 100)

• PTFE sealing discs (top and bottom covers - 2 required)

• Round cord seal (PTFE)

• M12 stud bolts (specify top M12×45 or bottom M12×55)

• M12 hex nuts and washers

• ETFE filter mesh (specify mesh size: 85-2000µm)

- All maintenance work must be performed by qualified personnel

- Use only original spare parts

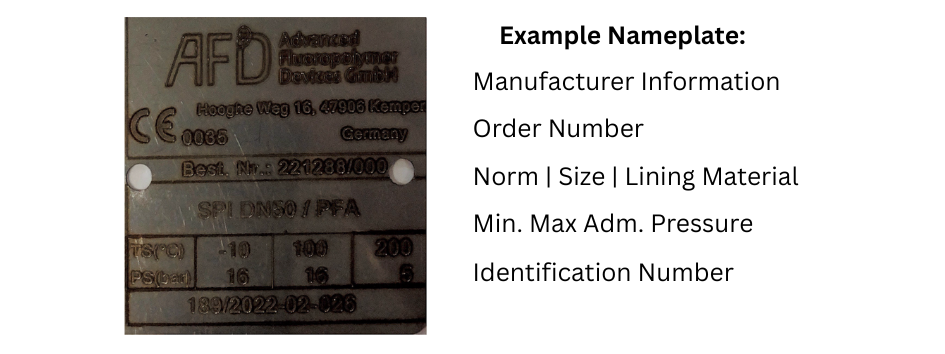

https://gft9.shop/pages/spare-parts-overview - Refer to valve identification data when ordering parts

- Observe all safety requirements (Section 7.3 - depressurize, isolate, drain)

9.1 Regular Inspection Schedule

Daily / Before Operation:

• Visual check for external leaks (covers, flanges)

• Check flush valve operation (if equipped)

• Verify no coating damage or rust spots

Weekly:

• Monitor differential pressure (if gauge equipped)

• Visual inspection of exterior condition

• Check cover bolt tightness (hand-check for looseness)

Monthly:

• Function test flush valve (if equipped)

• Verify flow direction arrow visible

• Check for process fluid staining (potential leak indicator)

Quarterly:

• Torque check on cover bolts (45 Nm - cross-cross pattern)

• Body coating inspection (touch up if needed)

• Basket inspection (may require removal for visual check)

Semi-Annual:

• Remove and clean strainer basket (per application requirements)

• Inspect ETFE mesh for tears or excessive debris

• Check PTFE seals for compression set

Annual / After Heavy Use:

• Full strainer inspection (remove both covers)

• Replace PTFE seals (top and bottom)

• Inspect body interior PFA lining for damage

• Pressure test strainer (verify no leaks)

9.2 Strainer Basket Removal

When Required:

• Clogged basket (high differential pressure)

• Scheduled cleaning interval

• Mesh inspection or replacement

• Round cord seal replacement

⚠ IMPORTANT: System must be fully depressurized and drained before opening

Procedure:

Step 1: Isolate and Prepare

• Close upstream and downstream isolation valves

• Depressurize system completely (verify with gauge)

• Drain residual fluid using bottom flush valve (if equipped)

• Apply lockout/tagout per company procedures

Step 2: Remove Top Cover

• Loosen 8× M12 nuts in cross-cross pattern (gradual loosening)

• Remove nuts and washers (place in clean container)

• Lift top cover vertically off body

• Set cover aside on clean surface

Step 3: Extract Strainer Basket

• Thread M8 ring bolt into central hole on basket top

• Pull basket vertically upward out of body

• ⚠ CAUTION: Residual fluid may drain from basket - have drip tray ready

• If basket sticks: Remove basket support and push from below (Section 8.2)

Step 4: Inspection Before Cleaning

• Check seal ring condition during removal

• Note debris type and quantity (for maintenance records)

• Inspect anti-rotation knob for damage

• Take photos if unusual wear patterns observed

9.3 Strainer Basket Cleaning

When Required:

• After removal per Section 9.2

• Visible debris accumulation

• High differential pressure indication

Cleaning Procedure:

Step 1: Initial Debris Removal

• Shake out loose debris into appropriate waste container

• If flush valve equipped: Basket can be flushed before removal

• Dispose of debris per process fluid safety guidelines

Step 2: Filter Mesh Cleaning

• Use soft brush to remove debris from ETFE mesh

• Brush from inside to outside (pushes debris out of mesh)

• Avoid metal brushes or abrasive pads (will damage PTFE components)

Step 3: Solvent Cleaning (if required)

• Use approved cleaning solution compatible with process fluid

• Soak basket in cleaning solution if heavily contaminated

• Ultrasonic cleaning permissible (if equipment available)

• Rinse thoroughly with clean solvent or DI water

Step 4: Drying

• Air dry completely before reinstallation

• May use compressed air (low pressure) to accelerate drying

• Inspect for cleanliness using backlighting (hold mesh to light)

Step 5: Post-Cleaning Inspection

• Inspect ETFE mesh for tears, holes, or separation

• ✓ PASS CRITERIA: No visible damage, mesh intact, no embedded debris

• If mesh damaged: Replace basket assembly (Section 9.4)

• If round cord damaged: Replace per Section 9.7

⚠ WARNING: Do not use abrasive cleaners, metal brushes, or high-pressure steam

9.4 Strainer Basket Installation

When Required:

• After cleaning per Section 9.3

• After mesh or seal replacement

• New basket installation

Procedure:

Step 1: Pre-Installation Inspection

• Verify basket clean and dry

• Verify ETFE mesh intact (no tears)

• Verify round cord seal present and properly seated

• Clean body interior if debris present

Step 2: Position Indicator Alignment

• Locate white position indicator knob on basket bottom

• Locate corresponding slot in body interior (PFA-lined cavity)

• ⚠ CRITICAL: Knob MUST align with slot for proper installation

Step 3: Basket Insertion

• Hold basket by top rim

• Align white knob with body slot

• Lower basket vertically into body

• Push down gently until basket seats on bottom seal surface

Step 4: Verify Installation

• Basket should sit flat (no tilting)

• Top rim of basket should be even with body top flange

• Test anti-rotation: Attempt to rotate basket slightly

• ✓ PASS: Basket resists rotation (knob engaged in slot)

• ✗ FAIL: Basket rotates freely - remove and re-align

Step 5: Top Cover Reinstallation

• Position PTFE sealing disc in top cover recess (verify centered)

• Lower top cover onto body (align with studs)

• ⚠ CAUTION: Do not drop cover (protects PFA lining)

• Install washers and nuts (hand-tight initially)

Step 6: Top Cover Torquing

• Torque Pattern: 1→5→3→7→2→6→4→8 (opposite bolt pairs)

• First Pass: 30 Nm (all 8 nuts)

• Second Pass: 45 Nm FINAL (all 8 nuts)

• Monitor gap around circumference during torquing

• Gap should be even (±0.5 mm variation maximum)

Step 7: Final Verification

• Measure gap at 4 locations: N, S, E, W

• Record measurements: _____ mm (all within ±0.5 mm)

• Verify no PTFE seal protrusion visible at joint

• Check flow direction arrow visible

9.5 Filter Mesh Replacement

When Required:

• ETFE mesh torn or damaged

• Mesh size change required for application

• Mesh degradation from temperature/chemical exposure

⚠ NOTE: Mesh replacement requires complete basket disassembly

Procedure:

Step 1: Basket Disassembly

• Remove strainer basket per Section 9.2

• Mark position of inner and outer tubes relative to round cord

• Pull round cord out of basket bottom groove (use pliers)

• Rotate and pull outer tube off inner tube assembly

Step 2: Remove Old Filter Mesh

• Unroll ETFE mesh from inner tube

• Note overlap direction for new mesh installation

• Inspect inner and outer tubes for damage

• Clean tubes if residue present

Step 3: Install New Filter Mesh

• Verify correct mesh size (85-2000µm as specified)

• Wrap ETFE mesh around inner tube

• Maintain overlap in same direction as original (typically 20-30mm)

• Ensure mesh covers full length of inner tube

Step 4: Reassemble Basket

• Slide outer tube over inner tube assembly

• ⚠ CRITICAL: Rotate WITH overlap direction (not against)

• Apply even pressure during sliding

• Insert tubes together into basket bottom

Step 5: Install Round Cord Seal

• Align tubes per original position markings

• Press round cord into basket bottom groove

• Cord should seat fully with no gaps or protrusions

• Leave approximately 10mm protruding for future removal

Step 6: Verify Assembly

• Check that mesh is secure between tubes

• Verify round cord seated properly

• Test-fit in body (verify anti-rotation engagement)

• Reinstall per Section 9.4

9.6 PTFE Seal Replacement (Top and Bottom Covers)

When Required:

• External leak at cover/body joint

• Annual preventive maintenance

• Seal compression set (permanent deformation)

• Visible damage to seal

Procedure:

Step 1: Cover Removal

• For top cover: Remove per Section 9.2

• For bottom cover: Remove 8× M12 nuts, lift cover off studs

Step 2: Remove Old PTFE Seal

• Lift seal out of cover recess

• Inspect seal for compression set (flattened areas)

• Note any unusual wear patterns for records

Step 3: Clean Seal Recess

• Remove any debris or residue from recess

• Wipe with lint-free cloth

• Verify recess not damaged or deformed

Step 4: Install New PTFE Seal

• Position new seal in cover recess

• Center seal concentrically (equal spacing all around)

• Press seal flat into recess (should sit flush)

• ⚠ CRITICAL: Seal must not protrude above cover surface

Step 5: Reinstall Cover

• For bottom cover: Verify inlet orientation correct

• Install per Section 9.4 (torque to 45 Nm)

• Verify gap even around circumference

Step 6: Pressure Test

• After reassembly, perform pressure test (per company procedures)

• Verify no leaks at reinstalled cover

• Check gap measurement (±0.5 mm)

9.7 Round Cord Seal Replacement

When Required:

• Internal bypass leakage (reduced filtration efficiency)

• Visible damage to cord during basket inspection

• Cord compression set or chemical degradation

Procedure:

Step 1: Basket Disassembly

• Remove and disassemble basket per Section 9.5, Step 1

• Pull old round cord out using pliers

• Inspect basket bottom groove for damage

Step 2: Clean Basket Bottom Groove

• Remove any residue from old cord

• Clean groove thoroughly with cloth

• Verify groove depth uniform (no damage)

Step 3: Install New Round Cord

• Obtain replacement cord (order correct diameter for size)

• Insert cord into basket bottom groove

• Press cord evenly into place using pliers

• Work around entire circumference

Step 4: Verify Installation

• Cord should seat fully in groove

• No gaps or voids around circumference

• Leave approximately 10mm protruding (aids future removal)

• Cord should not be stretched or compressed

Step 5: Reassemble Basket

• Reassemble per Section 9.5 (reverse order)

• Verify anti-rotation knob intact

• Reinstall basket per Section 9.4

9.8 Cover Bolt Maintenance

When Required:

• Semi-annual inspection

• After thermal cycling (first 24 hours of operation)

• If leaks detected at covers

• Thread damage suspected

Procedure:

Step 1: Visual Inspection

• Check all 8 stud bolts (top and bottom covers)

• Inspect for corrosion, thread damage, or bending

• Check washers for deformation

Step 2: Torque Verification

• Use calibrated torque wrench

• Check each nut: Target 45 Nm

• Follow cross-cross pattern: 1→5→3→7→2→6→4→8

• If any nut loose: Re-torque all nuts in sequence

Step 3: Thread Maintenance

• If studs corroded: Remove and replace

• Clean threads with wire brush if dirty

• Apply grease to threads during reinstallation

• Verify nuts thread smoothly (no binding)

Step 4: Fastener Replacement

• If threads damaged: Replace stud/nut immediately

• Order correct length: Bottom M12×55, Top M12×45

• Use only stainless steel grade 316 (or better)

• Apply anti-seize to threads during installation

Step 5: Establish Torque Check Schedule

• After initial heat-up: 24 hours

• High vibration service: Monthly

• Normal service: Semi-annually

• Document torque checks in maintenance log

9.9 Pressure Testing After Maintenance

When Required:

• After any cover removal/reinstallation

• After PTFE seal replacement

• After basket replacement

• Annual verification

⚠ NOTE: Pressure testing recommended before returning to service

Procedure:

Step 1: Visual Inspection

• Verify all covers installed and torqued to 45 Nm

• Check no tools or parts left inside strainer

• Verify flow direction correct

Step 2: Low Pressure Test (Air or Water)

• Close downstream isolation valve

• Slowly pressurize to 2-3 bar

• Inspect all joints for leaks

• Listen for air leaks (if using compressed air)

Step 3: Full Pressure Test

• Gradually increase to operating pressure

• Hold pressure for 5 minutes minimum

• Inspect cover joints for leakage

• Check basket area (look for bypass around seal)

Step 4: Leak Detection

• If leak detected: Depressurize immediately

• Identify leak location (cover, seal, basket)

• Re-torque bolts or replace seals as needed

• Repeat pressure test after repair

Step 5: Documentation

• Record test pressure: _____ bar

• Test duration: _____ minutes

• Result: ✓ PASS / ✗ FAIL

• Technician signature: __________

• Date: __________

9.10 Maintenance Records

Recommended Documentation:

• Date of maintenance

• Work performed (basket cleaning, seal replacement, etc.)

• Parts replaced (include part numbers and serial numbers)

• Torque values applied

• Gap measurements (top and bottom covers)

• Pressure test results

• Unusual observations or issues

• Technician name

• Next scheduled maintenance date

Example Maintenance Log Entry:

Date: 2026-01-15

Work: Basket cleaning, top cover PTFE seal replacement

Parts: PTFE seal (P/N: GSO-SEAL-TOP-DN80)

Torque: 45 Nm (verified all 8 top cover bolts)

Gap: 1.2mm average (N:1.2, S:1.1, E:1.3, W:1.2)

Pressure Test: 16 bar × 5 min - PASS

Notes: ETFE mesh in good condition, no tears observed

Tech: [Name]

Next Service: 2026-07-15 (6 months)