Advanced Fluoropolymer Devices GmbH

Precision Manufacturing Meets Transfer Molding

Installation and Operating Manual

Control Valve

PFA Lined Control Valve

Imperium9

This comprehensive manual provides detailed instructions for safe transport, installation, operation, and routine maintenance of your equipment.

Please review all sections carefully before proceeding. Keep this manual accessible for future reference.

Important Safety Notice

Carefully observe these operating instructions before transport, installation, operation, and maintenance!

Failure to follow proper procedures may result in equipment damage, personal injury, or voided warranty.

Manual Information

- Document Version: 1.0

- Last Updated: February 12, 2026

- Document Type: Installation and Operating Manual

- Language: English

Quick Reference Guide

📋 Before You Start

🚚 Transport Guidelines

⚙️ Installation Process

🔧 Operation Manual

🛠️ Maintenance Schedule

📞 Support Contact

| Parameter | Value |

|---|---|

| Name | Imperium9 |

| Operational characteristics | Equal percentage, Linear, On/Off |

| Design norm | DIN |

| Size | DN 15-100 |

| Flange dimensions | DIN 2501 (PN 16) | ASME B16.10 (Class 150-RF LP) |

| Face to face dimensions | PN (EN 558-1), Series 1 |

| Actuator | Actuated version available. |

| Plug and stem | Plug Guide: stem guided, optional: seat guided (V-plug, U-plug from DN 80 to DN 100) Rangeability: 1:25, V-plug 1:100 (min. kvs-value 0.01 m³/h to 1.2 m³/h) Bellows: all valves are in heavy-duty PFA bellows |

| Lining | PFA, PFA/AS, PVDF |

| Body | 1.0619 , 1.4308, 1.4408/ A216WCB, CF8-M or CF-8 |

| Pressure | 0.1 mbar vacuum to 16 bar (requires special bellows) |

| Temperature range | -60°C to +180°C |

| Leakage rate | leakage rate class VI |

| Custom | Heating jacket |

| Quality | Body 24 bar(P10|P11|P12), Dielectric strength test 15/20 kV, C4 external coating |

| Certificates | EU Pressure Equipment Directive 2014/68/EU |

DIN Weight Specifications

| Size DIN | Weight |

|---|---|

| DN 15 | 6 kg |

| DN 20 | 6 kg |

| DN 25 | 11 kg |

| DN 40 | 16 kg |

| DN 50 | 19 kg |

| DN 80 | 39 kg |

| DN 100 | 44 g |

ANSI Weight Specifications

| Size ANSI | Weight |

|---|---|

| NPS ½" | 6 kg |

| NPS ¾" | 6 kg |

| NPS 1" | 11 kg |

| NPS 1½" | 16 kg |

| NPS 2" | 19 kg |

| NPS 3" | 39 kg |

| NPS 4" | 44 kg |

DIN Pipe Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| DN 15 | 4 x M12 | 6 |

| DN 20 | 4 x M12 | 8 |

| DN 25 | 4 x M12 | 10 |

| DN 40 | 4 x M16 | 20 |

| DN 50 | 4 x M16 | 26 |

| DN 80 | 8 x M16 | 25 |

| DN 100 | 8 x M16 | 35 |

ANSI Pipe Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| NPS ½" | 4 x ½“ | 45/5 |

| NPS ¾" | 4 x ½“ | 55/6 |

| NPS 1" | 4 x ½“ | 70/8 |

| NPS 1½" | 4 x ½“ | 135/15 |

| NPS 2" | 4 x ⅝“ | 220/15 |

| NPS 3" | 4 x ⅝“ | 400/45 |

| NPS 4" | 8 x ⅝“ | 310/35 |

DIN Body Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| DN 15 | 4 x M12 | 35/310 |

| DN 20 | 4 x M12 | 35/310 |

| DN 25 | 4 x M12 | 35/310 |

| DN 40 | 4 x M16 | 45/398 |

| DN 50 | 4 x M16 | 45/398 |

| DN 80 | 8 x M16 | 50/442 |

| DN 100 | 8 x M16 | 60/531 |

ANSI Body Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| NPS ½" | 4 x M12 | 310/35 |

| NPS ¾" | 4 x M12 | 310/35 |

| NPS 1" | 4 x M12 | 310/35 |

| NPS 1½" | 4 x M16 | 398/45 |

| NPS 2" | 4 x M16 | 398/45 |

| NPS 3" | 8 x M20 | 442/50 |

| NPS 4" | 12 x M24 | 531 /80 |

DIN Cover Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| DN 15 | 4 x M10 | 30/226 |

| DN 20 | 4 x M10 | 30/226 |

| DN 25 | 4 x M12 | 50/442 |

| DN 40 | 4 x M12 | 50/442 |

| DN 50 | 4 x M12 | 50/442 |

| DN 80 | 8 x M12 | 50/442 |

| DN 100 | 8 x M12 | 50/442 |

ANSI Cover Screws

| Size | Screws | Tightening Torque [Nm] [Nm/lbs] |

|---|---|---|

| NPS ½" | 4 x 3/8" | 30/266 |

| NPS ¾" | 4 x 3/8" | 30/266 |

| NPS 1" | 4 x ½“ | 50/442 |

| NPS 1½" | 4 x ½“ | 50/442 |

| NPS 2" | 4 x ½“ | 50/442 |

| NPS 3" | 8 x ½“ | 50/442 |

| NPS 4" | 8 x ½“ | 50/442 |

DIN Seat Screws

| Size | Tightening Torque [Nm] [Nm/lbs] |

|---|---|

| DN 15 | 3/26 |

| DN 20 | 3/26 |

| DN 25 | 6/53 |

| DN 40 | 12/106 |

| DN 50 | 16/142 |

| DN 80 | 28/248 |

| DN 100 | 30/265 |

ANSI Seat Screws

| Size | Tightening Torque [Nm] [Nm/lbs] |

|---|---|

| NPS ½" | 3/26 |

| NPS ¾" | 3/26 |

| NPS 1" | 6/53 |

| NPS 1½" | 12/106 |

| NPS 2" | 16/142 |

| NPS 3" | 28/248 |

| NPS 4" | 30/265 |

DIN Flow Rate

| Size | KVS Value |

|---|---|

| DN 15 | V Plugs (Seat in Ø: 8/8/8/8/8/8 mm): 0,01(0,012)/0,02(0,023)/0,05(0,06)/0,1(0,12)/0,2(0,23)/0,5(0,58) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/8/15mm): 1,2(1,4)/2,0(2,3)/4,0(4.7) m3/h(USgpm) |

| DN 20 | V Plugs (Seat in Ø: 8/8/8/8 mm): 0,05(0,06)/0,1(0,12)/0,2(0,23)/0,5(0,58) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/8/15mm): 1,2(1,4)/2,0(2,3)/4,0(4.7) m3/h(USgpm) |

| DN 25 | V Plugs (Seat in Ø: 8/14/14/14/14/14/14/14 (mm): 0,01(0,012)/0,02(0,23)/0,05(0,06)/0,10(0,12)/0,20(0,23)/0,50(0,58)/0,80(0,93)/1,20(1,4) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/15/20/25mm): 2,00(2,3)/4(4,7)/7(8.2)/11(12,8) m3/h(USgpm) |

| DN 40 | Parabol-plugs(Seat in Ø: 15/20/25/30/40mm): 4(4,7)/7(8.2)/11(12,8)/15(17,5)/28(32,6) m3/h(USgpm) |

| DN 50 | Parabol-plugs(Seat in Ø: 15/20/25/30/40/50mm): 4(4,7)/7(8.2)/11(12,8)/15(17,5)/28(32,6)/42(48,9) m3/h(USgpm) |

| DN 80 | Parabol-plugs(Seat in Ø: 30/40/50/65/80 mm): 15(17,5)/28(32,6)/42(48,9)/65(75,7)/ 100(117) m3/h(USgpm) U-Plugs(Seat in Ø: 80): 90(105) m3/h(USgpm) |

| DN 100 | Parabol-plugs(Seat in Ø: 50/65/80/96 mm): 42(48,9)/65(75,7)/ 100(117)/155(180) m3/h(USgpm) U-Plugs(Seat in Ø: 80/96): 90(105)/135(157) m3/h(USgpm) |

ANSI Flow Rate

| Size | CV Value |

|---|---|

| NPS ½" | V Plugs (Seat in Ø: 8/8/8/8/8/8 mm): 0,01(0,012)/0,02(0,023)/0,05(0,06)/0,1(0,12)/0,2(0,23)/0,5(0,58) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/8/15mm): 1,2(1,4)/2,0(2,3)/4,0(4.7) m3/h(USgpm) |

| NPS ¾" | V Plugs (Seat in Ø: 8/8/8/8 mm): 0,05(0,06)/0,1(0,12)/0,2(0,23)/0,5(0,58) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/8/15mm): 1,2(1,4)/2,0(2,3)/4,0(4.7) m3/h(USgpm) |

| NPS 1" | V Plugs (Seat in Ø: 8/14/14/14/14/14/14/14 (mm): 0,01(0,012)/0,02(0,23)/0,05(0,06)/0,10(0,12)/0,20(0,23)/0,50(0,58)/0,80(0,93)/1,20(1,4) m3/h(USgpm) Parabol-plugs(Seat in Ø: 8/15/20/25mm): 2,00(2,3)/4(4,7)/7(8.2)/11(12,8) m3/h(USgpm) |

| NPS 1½" | Parabol-plugs(Seat in Ø: 15/20/25/30/40mm): 4(4,7)/7(8.2)/11(12,8)/15(17,5)/28(32,6) m3/h(USgpm) |

| NPS 2" | Parabol-plugs(Seat in Ø: 15/20/25/30/40mm): 4(4,7)/7(8.2)/11(12,8)/15(17,5)/28(32,6) m3/h(USgpm) |

| NPS 3" | Parabol-plugs(Seat in Ø: 30/40/50/65/80 mm): 15(17,5)/28(32,6)/42(48,9)/65(75,7)/ 100(117) m3/h(USgpm) U-Plugs(Seat in Ø: 80): 90(105) m3/h(USgpm) |

| NPS 4" | Parabol-plugs(Seat in Ø: 50/65/80/96 mm): 42(48,9)/65(75,7)/ 100(117)/155(180) m3/h(USgpm) U-Plugs(Seat in Ø: 80/96): 90(105)/135(157) m3/h(USgpm) |

DIN Cavitation Coefficient

| Size | Cavitation Coefficient Z for Seat ø |

|---|---|

| DN 15 | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| DN 20 | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| DN 25 | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| DN 40 | Seat in Ø (15/20/25/30/40): 0,6/0,6/0,55/0,5 |

| DN 50 | Seat in Ø (20/25/30/40/50): 0,6/0,6/0,55/0,5/0,4 |

| DN 80 | Seat in Ø (30/40/50/65/80): 0,55/0,5/0,45/0,32/0,3 |

| DN 100 | Seat in Ø (50/65/80/96): 0,47/0,33/0,3/0,26 |

ANSI Cavitation Coefficient

| Size | Cavitation Coefficient Z for Seat ø |

|---|---|

| NPS ½" | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| NPS ¾" | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| NPS 1" | Seat in Ø (8/14/15): 0,6/0,6/0,6 |

| NPS 1½" | Seat in Ø (15/20/25/30/40): 0,6/0,6/0,55/0,5 |

| NPS 2" | Seat in Ø (20/25/30/40/50): 0,6/0,6/0,55/0,5/0,4 |

| NPS 3" | Seat in Ø (30/40/50/65/80): 0,55/0,5/0,45/0,32/0,3 |

| NPS 4" | Seat in Ø (50/65/80/96): 0,47/0,33/0,3/0,26 |

𝑋𝐹 = ∆𝑝 / 𝑝1−𝑝𝑣

Variable definition:

XF = Differential pressure ratio

p1 = Absolute pressure at inlet

pv = Vapour pressure at operating temp

Δp = Differential pressure input/outlet

Result interpretation:

XF ≤ z : non-critical conditions

XF ≤ 1,4 x z : tolerable cavitation

XF > 1,4 x z : inadmissible cavitation

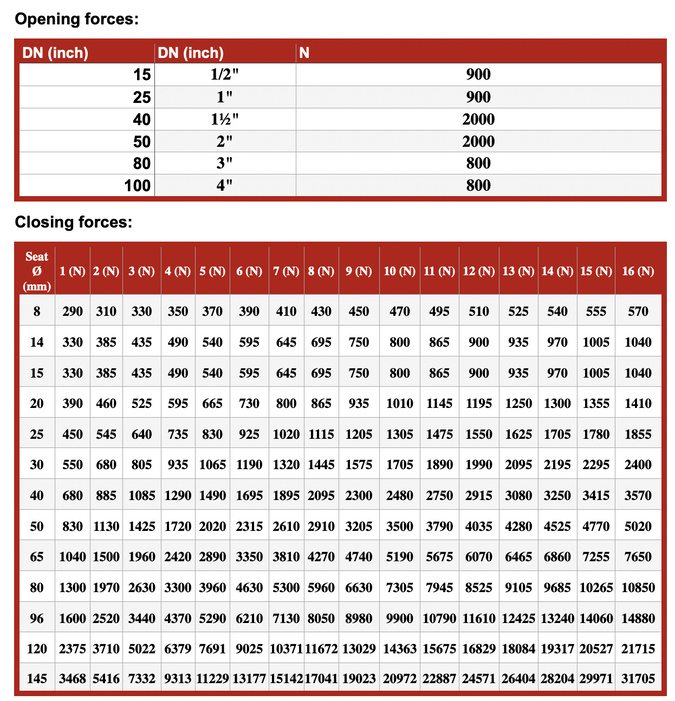

The values specified in the tables apply to a seat/plug material of PTFE. With other materials, e.g. PTFE/carbon, higher closing forces are required. Please inquire at

manufacturer's.

If the maximum Δp is < p2, p2 is used in the tables. observe the application limits acc. to the pressure-temperature diagram in Section 1.6.

A mechanical travel stop is required in the area marked. It is provided when:

Δp > 10 bar / 145 psi to Seat-Ø 15-50 mm

Δp > 6 bar / 87 psi to Seat-Ø ≥ 65 mm

Control Valve P-T-Diagram for different Bellow Configurations

10. Dimensional Drawings

10.1 Dimensional Measurements DIN

| Size | L | H | ød | øk | øD | Bolting | Weight |

|---|---|---|---|---|---|---|---|

| DN 15 | 130 mm | 130 mm | 45 mm | 65 mm | 95 mm | 4 x 14 (M12) | 6 kg |

| DN 20 | 150 mm | 130 mm | 58 mm | 75 mm | 105 mm | 4 x 14 (M12) | 6 kg |

| DN 25 | 160 mm | 185 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 11 kg |

| DN 40 | 200 mm | 225 mm | 88 mm | 110 mm | 150 mm | 4 x 18 (M16) | 16 kg |

| DN 50 | 230 mm | 230 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 19 kg |

| DN 80 | 310 mm | 340 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 39 kg |

| DN 100 | 350 mm | 350 mm | 158 mm | 180 mm | 220 mm | 8 x 18 (M16) | 44 g |

10.2 Dimensional Measurements ANSI

| Size | L1 | H | ød | øk | øD | Bolting | Weight |

|---|---|---|---|---|---|---|---|

| NPS ½" | 130 mm | 130 mm | 34,9 mm | 60,3 mm | 88,9 mm | 4 x 15.9 | 6 kg |

| NPS ¾" | 130 mm | 130 mm | 42,9 mm | 69,8 mm | 98,4 mm | 4 x 15.9 | 6 kg |

| NPS 1" | 160 mm | 185 mm | 50,8 mm | 79,4 mm | 108 mm | 4 x 15.9 | 11 kg |

| NPS 1½" | 200 mm | 225 mm | 73 mm | 98,4 mm | 127 mm | 4 x 15.9 | 16 kg |

| NPS 2" | 230 mm | 230 mm | 92,1 mm | 121 mm | 152,4 mm | 4 x 19 | 19 kg |

| NPS 3" | 310 mm | 340 mm | 127 mm | 152,4 mm | 190,5 mm | 4 x 19 | 39 kg |

| NPS 4" | 350 mm | 350 mm | 157,2 mm | 190 mm | 228,6 mm | 8 x 19 | 44 kg |

11. Sectional Drawing

| Pos. | Item | Material |

|---|---|---|

| 1 | Body | 1.0619 or 1.4308/1.4408/1.4409 | A216/WCB,CF8/CF8M/CF3M |

| 2 | Lining | PFA Perfluoralkoxy (standard) or PFA-LantistaticF-L (on request) |

| 3.1 | Trim Variant 1 | Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow (standard)) |

| 3.2 | Trim Variant 2 | V-Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow) |

| 3.3 | Trim Variant 3 | U Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow (standard)) |

| 4 | Bellow | PFA |