PFA Lined Strainer

Key Specifications

About GFT9 – Your Trusted PFA Specialist

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

PFA Beklede Filteroplossingen | DN 25 - 150 | GFT9 Overzicht Features

Our PFA Beklede Filteroplossingen | DN 25 - 150 | GFT9 Overzicht Certificates

Purion9 Measurements

DIN Standards

| Size | L | H | H2 | ød | øk | øD | Bolting | Weight |

|---|---|---|---|---|---|---|---|---|

| DN 25 | 160 mm | 175 mm | 110 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 7 kg |

| DN 50 | 230 mm | 220 mm | 140 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 18 kg |

| DN 80 | 310 mm | 320 mm | 150 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 28 kg |

| DN 100 | 350 mm | 330 mm | 160 mm | 158 mm | 180 mm | 220 mm | 8 x 18 (M16) | 80 kg |

| DN 150 | 480 mm | 212 mm | 240 mm | 285 mm | 8 x 22 (M20) |

ANSI Standards

| Size | L | L2 | H | H2 | ød | øk | øD | Bolting | Weight |

|---|---|---|---|---|---|---|---|---|---|

| NPS 1" | 160 mm | 160 mm | 175 mm | 110 mm | 50,8 mm | 79,4 mm | 108 mm | 4 x 15.9 | 7 kg |

| NPS 2" | 230 mm | 230 mm | 220 mm | 140 mm | 92,1 mm | 121 mm | 152,4 mm | 4 x 19 | 18 kg |

| NPS 3" | 310 mm | 310 mm | 320 mm | 150 mm | 127 mm | 152,4 mm | 190,5 mm | 4 x 19 | 28 kg |

| NPS 4" | 350 mm | 350 mm | 330 mm | 160 mm | 157,2 mm | 190 mm | 228,6 mm | 8 x 19 | 80 kg |

| NPS 6" (on request) | 480 mm | 216 mm | 241 mm | 279 mm | 8 x 22.2 |

Purion9 Materials

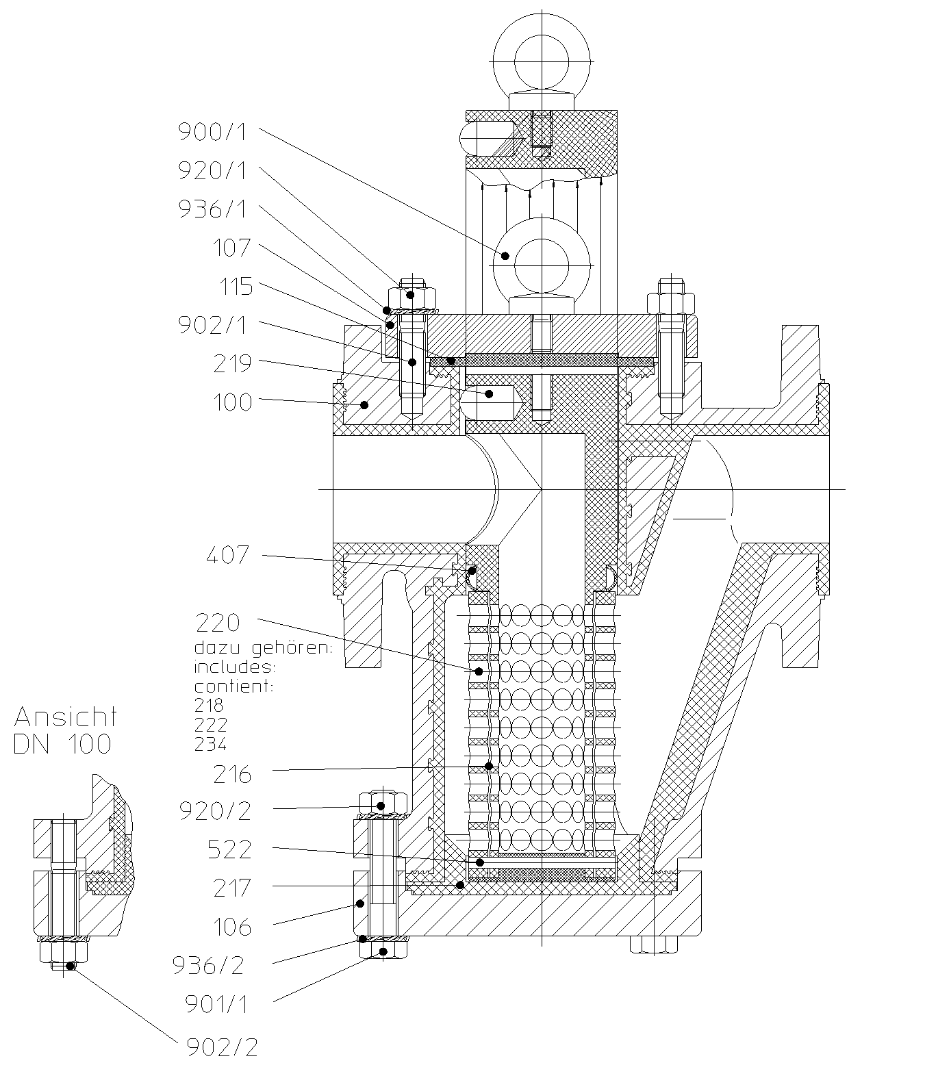

| Pos. | Item | Material |

|---|---|---|

| 99 | PFA Virgin | |

| 100 | 1.0619 (A216 WCB) | |

| 106 | 1.0619 (A216 WCB) | |

| 107 | 1.0619 (A216 WCB) | |

| 109 | 1.0619 (A216 WCB) | |

| 115 | 1.0619 (A216 WCB) | |

| 216 | ETFE | |

| 217 | 1.0619 (A216 WCB) | |

| 219 | PTFE / PTFE Carbon Composite | |

| 220 | PTFE / PTFE Carbon Composite | |

| 218 | PTFE / PTFE Carbon Composite | |

| 222 | PTFE / PTFE Carbon Composite | |

| 234 | PTFE / PTFE Carbon Composite | |

| 407 | PTFE / PTFE Carbon Composite | |

| 522 | PTFE / PTFE Carbon Composite | |

| 900 | Stainless steel | |

| 901 | Stainless steel | |

| 902 | Stainless steel | |

| 920 | Stainless steel | |

| 936 | Stainless steel |

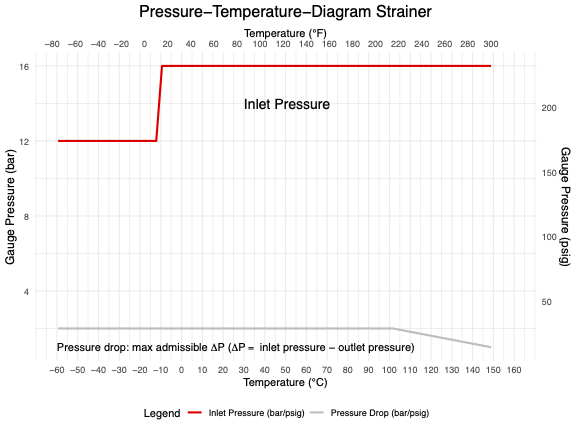

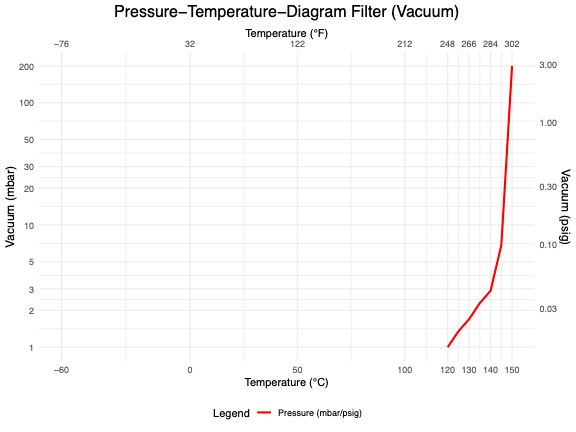

Pressure Temperature Diagram

Industry Applications

The PFA Lined Strainer is engineered for industries that deal with aggressive, corrosive, and high-temperature media. Its virgin PFA lining ensures long-lasting protection against aggressive chemicals, while the mechanical clamping system provides a secure, vacuum-tight seal for worry-free operation. Designed for high-efficiency filtration, the strainer also offers conductive PFA options to protect against electrostatic discharge in hazardous environments. Whether it's preventing contamination in pharmaceutical production or providing safety in petrochemical processes, the PFA Lined Strainer guarantees optimal performance across a wide range of industrial applications.

Chemical Processing

Water Treatment

Petrochemical

Pharmaceutical

Food & Beverage

Oil & Gas

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.