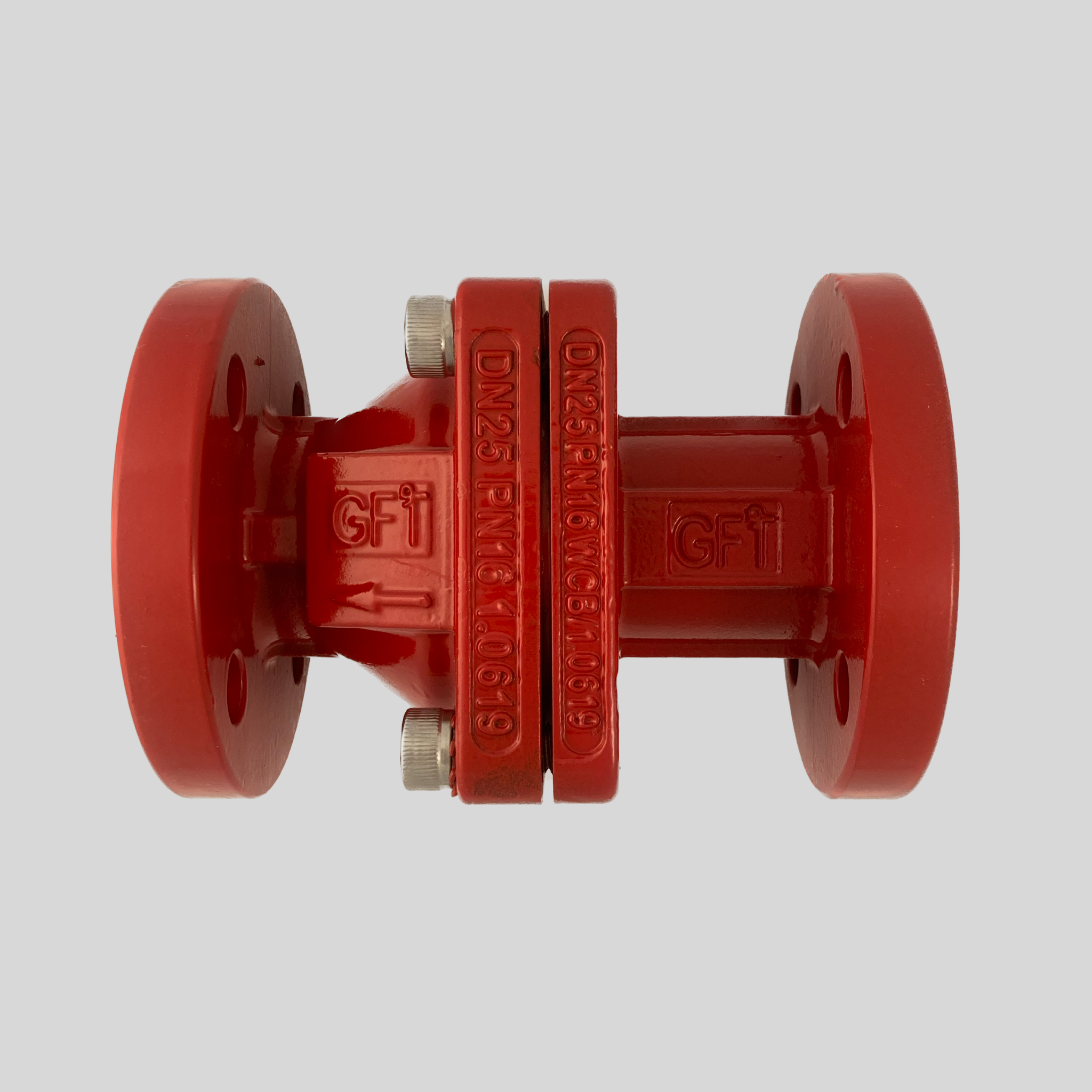

PFA Lined Ball Check Valve

Key Specifications

Partner with GFT9

Global Reach

Manufacturer

Dependable

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

PFA-beklede Kogelterugslagklep | DN 25-100 | Betrouwbare Terugslagpreventie Features

Our PFA-beklede Kogelterugslagklep | DN 25-100 | Betrouwbare Terugslagpreventie Certificates

Prohibron9 Measurements

DIN Standards

| Size | L | ød | øk | øD | Bolting | Kvs | Weight |

|---|---|---|---|---|---|---|---|

| DN 25 | 160 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 27 | 4,9 kg |

| DN 40 | 200 mm | 88 mm | 110 mm | 150 mm | 4 x 18 (M16) | 97 | 8,9 kg |

| DN 50 | 230 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 122 | 12 kg |

| DN 80 | 310 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 300 | 26 kg |

| DN 100 | 350 mm | 158 mm | 180 mm | 220 mm | 8 x 18 (M16) | 410 | 35 kg |

| DN 150 | 480 mm | 212 mm | 240 mm | 285 mm | 8 x 22 (M20) | 360 | 70 kg |

ANSI Standards

| Size | L | ød | øk | øD | Bolting | Cv | Weight |

|---|---|---|---|---|---|---|---|

| NPS 1" | 160 mm | 50,8 mm | 79,4 mm | 108 mm | 4 x 15.9 | 31 | 4,9 kg |

| NPS 1½" | 200 mm | 73 mm | 98,4 mm | 127 mm | 4 x 15.9 | 113 | 8,9 kg |

| NPS 2" | 230 mm | 92,1 mm | 120,5 mm | 152,4 mm | 4 x 19 | 142 | 12 kg |

| NPS 3" | 310 mm | 127 mm | 152,5 mm | 190,5 mm | 4 x 19 | 348 | 26 kg |

| NPS 4" | 350 mm | 157,2 mm | 190,5 mm | 228,6 mm | 8 x 18 | 476 | 35 kg |

| NPS 6" | 394 mm | 216 mm | 241 mm | 279 mm | 8 x 22.2 | 418 | 70 kg |

Prohibron9 Materials

| Pos. | Item | Material |

|---|---|---|

| 1 | Body | 1.0619 , 1.4308, 1.4408/ A216WCB, CF8-M or CF-8 |

| 2 | Lining | PFA, PFA/AS, FEP, PVDF |

| 3 | Ball | PTFE massive or hollow |

| 5 | Bolts, Nuts and Screws | A2/A4-70 Stainless Steel |

Pressure Temperature Diagram

Industry Applications

PFA-lined components are essential in industries that handle aggressive or high-purity fluids. Thanks to PFA’s exceptional chemical resistance, the Prohibron9 can be used with strong acids, bases, solvents, and even permeating agents without degrading. Its high thermal stability, non-stick surface, and low permeability enable safe and efficient operation even in high-temperature and pressure conditions, reducing product contamination and material wear. These properties make PFA-lined ball check valves especially suitable for industries where fluid purity, corrosion resistance, and low maintenance are vital. From chemical plants to pharmaceutical production, the Prohibron9 ensures reliable backflow prevention under chemically and mechanically demanding conditions.

Chemical Processing

Fine Chemicals

Pharmaceuticals & Biotechnology

Petrochemical Industry

Pulp and Paper

Mining and Metallurgy

Water & Wastewater Treatment

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.