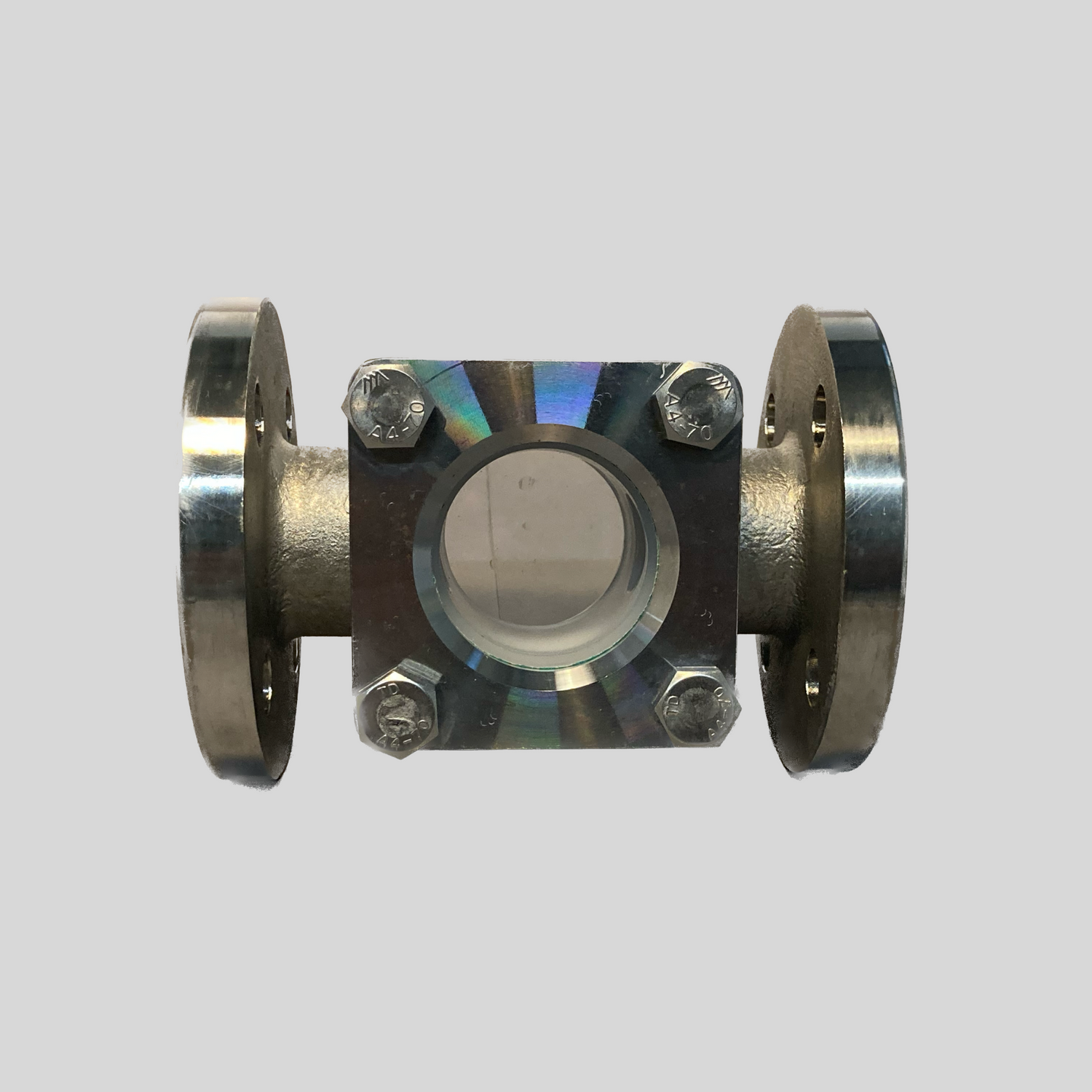

Clean Room Serie

Designed for GMP Compliance

Technical Specifications

| Size Range (DN) | DN 15 – DN 100 |

| Size Range (NPS) | ½" – 4" |

| Pressure Rating (DIN) | PN 16 |

| Pressure Rating (ANSI) | Class 150 |

| Temperature Range |

-20°C to +180°C (-4°F to +356°F

Extended range on request |

| Body Material (Standard) | - |

| Body Material (Clean Room) | Stainless Steel 1.4408 (CF8M), 1.4571, electropolished finish available |

| Lining Material | Virgin PFA (Perfluoroalkoxy), cleanroom processed |

| Lining Thickness | 2.5 – 3.5 mm |

| Face-to-Face Standard | EN 558-1 |

| Flange Standard (DIN) | EN 1092-1 |

| Flange Standard (ANSI) | ASME B16.5 |

| Certifications | PED 2014/68/EU, ISO 9001:2015, FDA/USP Class VI material compatibility |