PFA Lined Swing Check Valve

Key Specifications

Partner with GFT9

Global Reach

Manufacturer

Dependable

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

Swing Check Valve Leaflet Features

Our Swing Check Valve Leaflet Certificates

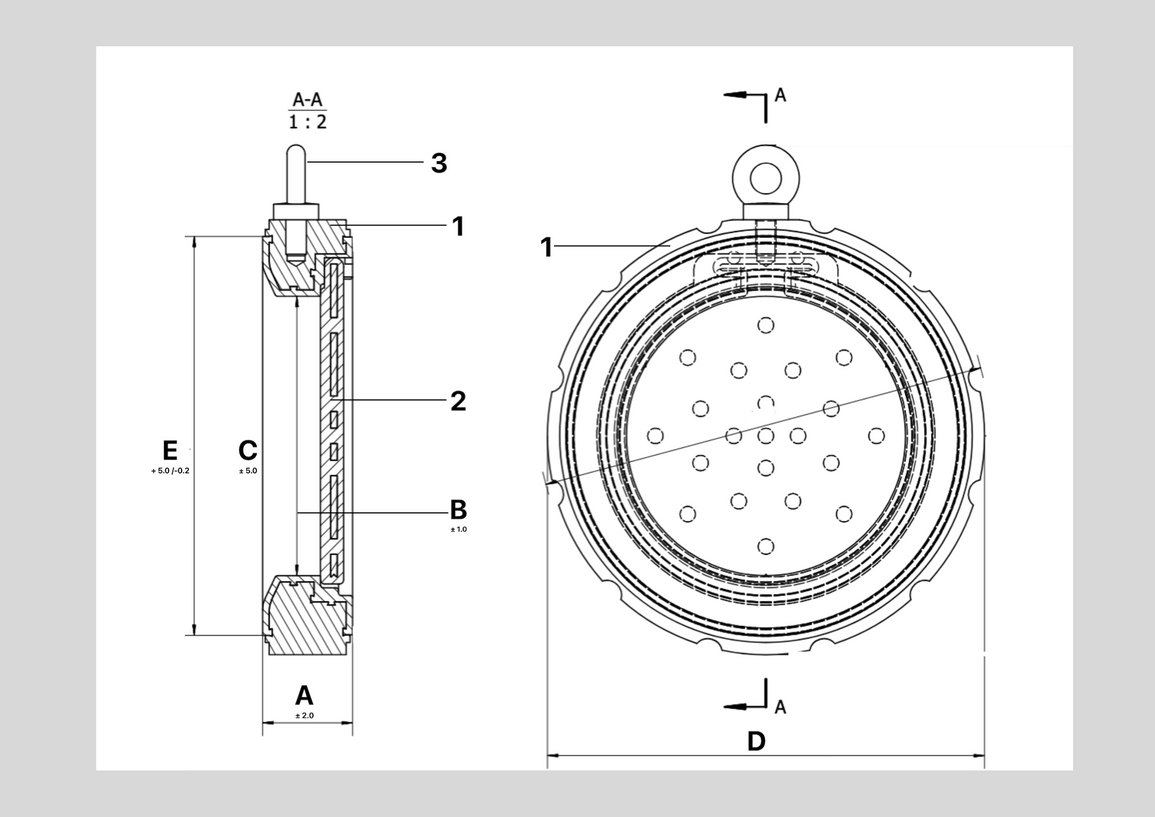

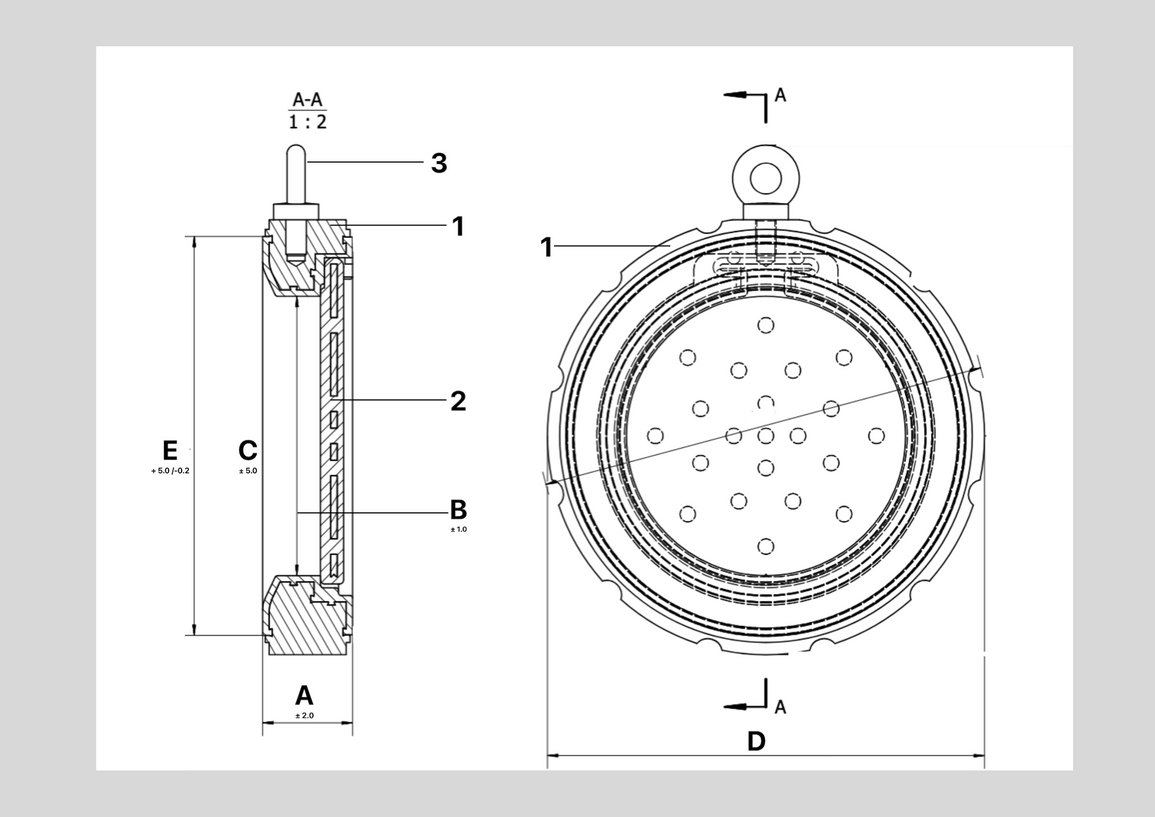

Vibron9 Measurements

DIN Standards

| Size | A | B | C | D | E | Pipe Min | Pipe Max | Opening |

|---|---|---|---|---|---|---|---|---|

| DN 40 | 33 mm | 20 mm | 35 mm | 95 mm | 70 mm | 35 mm | 46 mm | 52° |

| DN 50 | 43 mm | 30 mm | 52 mm | 110 mm | 90 mm | 46 mm | 56 mm | 52° |

| DN 80 | 46 mm | 42 mm | 64 mm | 142 mm | 124 mm | 73 mm | 82 mm | 52° |

| DN 100 | 52 mm | 65 mm | 80 mm | 180 mm | 152 mm | 95 mm | 100 mm | 60° |

| DN 150 | 56 mm | 111 mm | 128 mm | 295 mm | 260 mm | 192 mm | 195 mm | 60° |

| DN 250 | 68 mm | 184 mm | 224 mm | 348 mm | 317 mm | 242 mm | 260 mm | 52° |

| DN 300 | 78 mm | 232 mm | 272 mm | 398 mm | 367 mm | 292 mm | 310 mm | 52° |

| DN 350 | 92 mm | 252 mm | 297 mm | 426 mm | 397 mm | 315 mm | 330 mm | 48° |

| DN 400 | 102 mm | 327 mm | 370 mm | 510 mm | 470 mm | 380 mm | 390 mm | 45° |

ANSI Standards

| Size | A | B | C | D | E | Pipe Min | Pipe Max | Opening |

|---|---|---|---|---|---|---|---|---|

| NPS 1 1/2" | 33 mm | 20 mm | 35 mm | 95 mm | 70 mm | 35 mm | 46 mm | 52° |

| NPS 2" | 43 mm | 30 mm | 52 mm | 110 mm | 90 mm | 46 mm | 56 mm | 52° |

| NPS 3" | 46 mm | 42 mm | 64 mm | 142 mm | 124 mm | 73 mm | 82 mm | 52° |

| NPS 4" | 52 mm | 65 mm | 80 mm | 180 mm | 152 mm | 95 mm | 100 mm | 60° |

| NPS 6" | 56 mm | 111 mm | 128 mm | 207 mm | 145 mm | 150 mm | 150 mm | 60° |

| NPS 8" | 60 mm | 133 mm | 175 mm | 295 mm | 260 mm | 192 mm | 195 mm | 60° |

| NPS 10" | 68 mm | 184 mm | 224 mm | 348 mm | 317 mm | 242 mm | 260 mm | 52° |

| NPS 12" | 78 mm | 232 mm | 272 mm | 298 mm | 267 mm | 292 mm | 310 mm | 52° |

| NPS 14" | 92 mm | 252 mm | 297 mm | 426 mm | 397 mm | 315 mm | 330 mm | 48° |

| NPS 16" | 102 mm | 327 mm | 370 mm | 510 mm | 470 mm | 380 mm | 390 mm | 45° |

Vibron9 Materials

| Pos. | Item | Material |

|---|---|---|

| 1 | Lined Body | WCB, CF8 - PFA Lined |

| 2 | Disc | WCB, CF8 - PFA Lined |

| 3 | Eye Bolt | Stainless Steel |

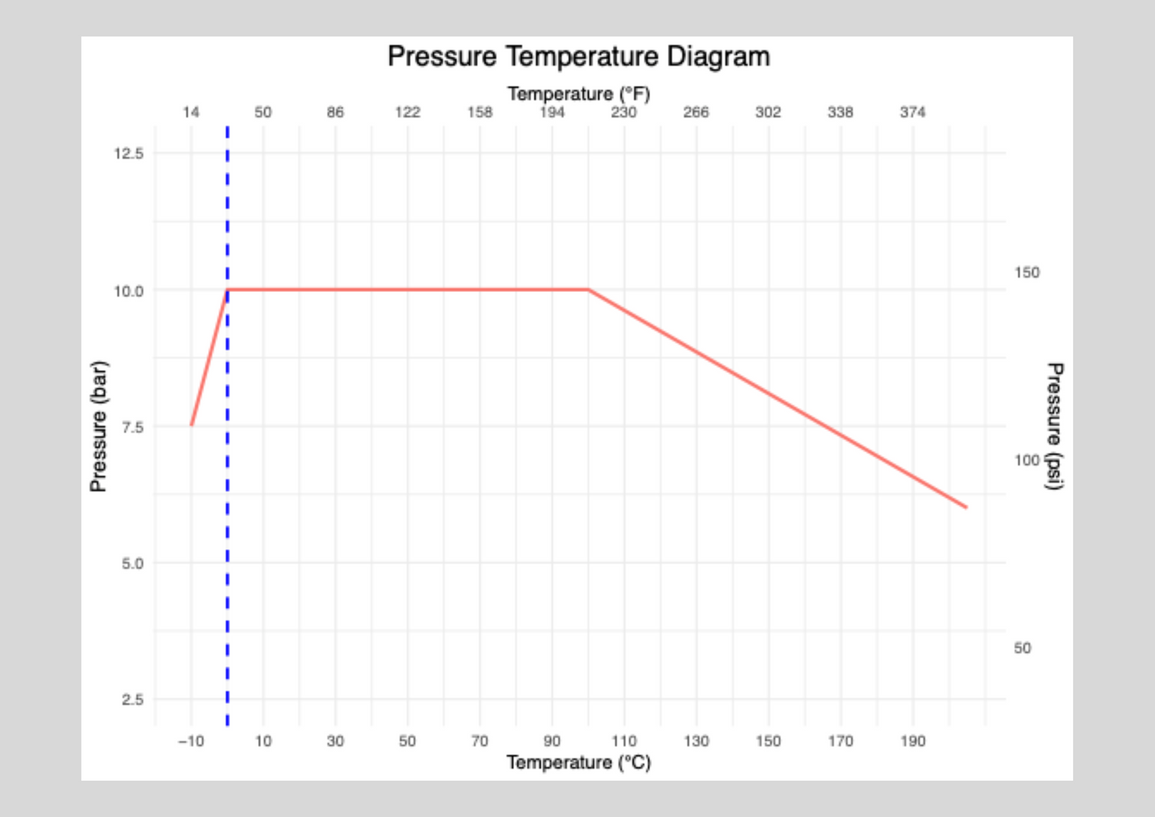

Pressure Temperature Diagram

Industry Applications

PFA (perfluoroalkoxy) is prized for its outstanding corrosion resistance, wide temperature tolerance, and non-stick surface—essential wherever fluid purity, safety, and uptime cannot be compromised. The Vibron9 leverages these properties to outperform conventional non-lined or metal check valves: Corrosion Resistance: Handles strong acids, bases, solvents, and permeating agents without degradation. Thermal Stability: Operates reliably from –40 °C to +150 °C, covering most industrial process ranges. Non-Stick Surface: Prevents buildup of viscous or sticky media, ensuring prompt valve action. Vacuum-Tight Seal: Mechanical clamping of the PFA liner guarantees leak-free performance even under negative pressure. These characteristics make Vibron9 the go-to check valve for any application demanding both backflow prevention and stringent chemical compatibility.

Chemical Processing

Petrochemical & Refining

Pharmaceutical & Biotech

Pulp & Paper

Mining & Mineral Processing

Oil & Gas Production

Water & Wastewater Treatment

Semiconductor Manufacturing

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.