PFA Lined Sample Valve

Key Specifications

Partner with GFT9

Global Reach

Manufacturer

Dependable

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

PFA kaplamalı Numune Alma Vana | DN 25 & 50 | Hassas Numune Alma Features

Our PFA kaplamalı Numune Alma Vana | DN 25 & 50 | Hassas Numune Alma Certificates

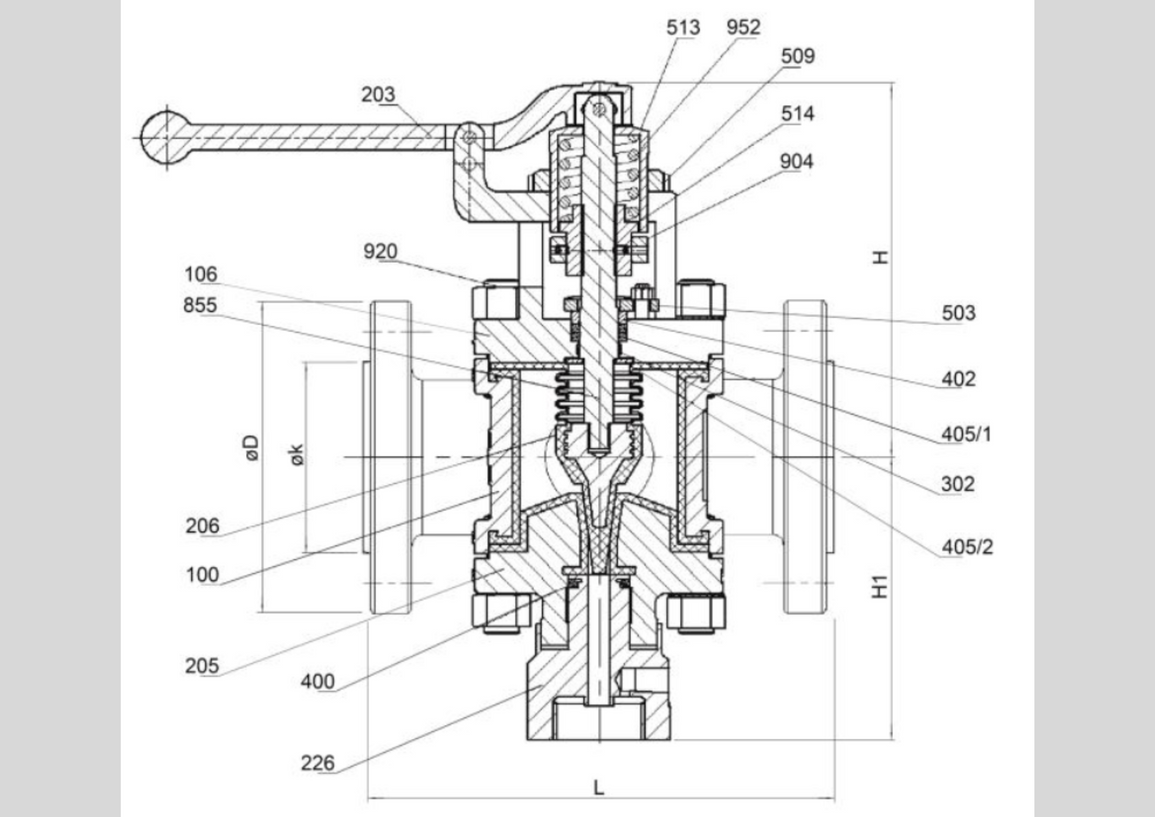

Provaron9 Measurements

DIN Standards

| Size | L | H | H2 | ød | øk | øD | Bolting | Kvs | Weight |

|---|---|---|---|---|---|---|---|---|---|

| DN 25 | 160 mm | 190 mm | 123 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 15 | Sampling - Conical 0,385 / Flat 2,56 Cone | 10 kg |

| DN 40 | 200 mm | 250 mm | 127 mm | 88 mm | 110 mm | 150 mm | 4 x 18 (M16) | 47 | Sampling - Conical 0,385 / Flat 2,56 Cone | 18 g |

| DN 50 | 230 mm | 195 mm | 131 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 65 | Sampling - Conical 0,385 / Flat 2,56 Cone | 18 kg |

| DN 80 | 310 mm | 310 mm | 173 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 200 | Sampling - Conical 0,385 / Flat 2,56 Cone | 18 g |

ANSI Standards

| Size | L2 | H | H2 | ød | øk | øD | Bolting | Cv | Weight |

|---|---|---|---|---|---|---|---|---|---|

| NPS 1" | 160 mm | 190 mm | 123 mm | 50,8 mm | 79,4 mm | 108 mm | 4 x 15.9 | 17,5 | Sampling - Conical 0,448 / Flat 2,98 Cone | 10 kg |

| NPS 1½" | 200 mm | 250 mm | 127 mm | 73 mm | 98,4 mm | 127 mm | 4 x 15.9 | 54,8 | Sampling - Conical 0,448 / Flat 2,98 Cone | 18 kg |

| NPS 2" | 165 mm | 195 mm | 131 mm | 92,1 mm | 121 mm | 152,4 mm | 4 x 19 | 75,7 | Sampling - Conical 0,448 / Flat 2,98 Cone | 18 kg |

| NPS 3" | 200 mm | 310 mm | 173 mm | 127 mm | 152,4 mm | 190,5 mm | 4 x 19 | 233 | Sampling - Conical 0,448 / Flat 2,98 Cone | 18 kg |

Provaron9 Materials

| Pos. | Item | Material |

|---|---|---|

| 100 | Body | 1.0619 (A216 WCB)/PFA* |

| 106 | Cover | Stainless Steel |

| 203 | Lever | Stainless Steel |

| 205 | Valve Seat | 1.0619 (A216 WCB) |

| 206 | Bellows | PTFE |

| 226 | Flange Connection | Modified PTFE |

| 302 | Guide Ring | PTFE-Carbon |

| 400 | O-Ring | FKM |

| 402 | Packing Ring | PTFE |

| 405.1/2 | Pressure Ring | Stainless Steel |

| 509 | Stuffing Box | Stainless Steel |

| 514 | Nut | HDPE |

| 904 | Spring Cap | Stainless Steel |

| 920 | Spring Bushing | Stainless Steel |

| 952 | Threaded Pin | Stainless Steel |

| 954 | Nut | Stainless Steel |

| 956 | Compression Spring | Stainless Steel |

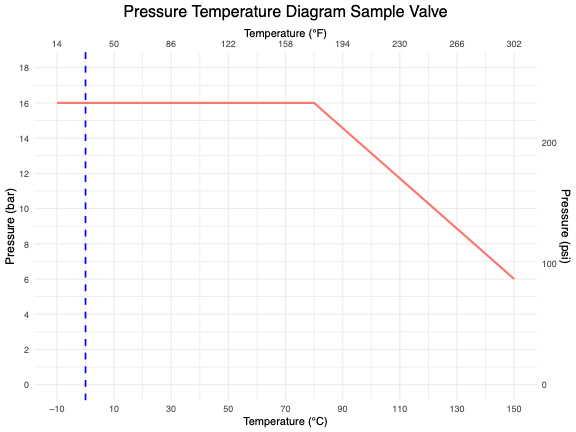

Pressure Temperature Diagram

Industry Applications

The Provaron9 sample valve, with its virgin PFA lining and gas-tight PTFE bellows seal, is built to meet the highest safety and purity standards in process industries. Its resistance to highly corrosive, permeating, or reactive media makes it especially valuable where traditional materials like stainless steel or standard plastics fall short. From toxic sampling in chemical plants to aseptic draws in pharmaceutical lines, the Provaron9 delivers repeatable performance and total process containment — making it an essential tool wherever sampling accuracy, operator protection, and product integrity are non-negotiable.

Pharmaceutical & Biopharma

Chemical & Fine Chemicals

Food & Beverage

Oil & Gas

Battery & Electronics Production

Water & Wastewater Treatment

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.