PFA Lined Control Valve

Key Specifications

Partner with GFT9

Global Reach

Manufacturer

Dependable

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

"GFT9 | PFA-ausgekleidete Regelventile | Langlebig & sicher bei aggressiven Medien" Features

Our "GFT9 | PFA-ausgekleidete Regelventile | Langlebig & sicher bei aggressiven Medien" Certificates

Imperium9 Measurements

DIN Standards

| Size | L | H | ød | øk | øD | Bolting | Kvs | Weight |

|---|---|---|---|---|---|---|---|---|

| DN 15 | 130 mm | 130 mm | 45 mm | 65 mm | 95 mm | 4 x 14 (M12) | VPLugs: | 6 kg |

| DN 20 | 150 mm | 130 mm | 58 mm | 75 mm | 105 mm | 4 x 14 (M12) | 6 kg | |

| DN 25 | 160 mm | 185 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 11 kg | |

| DN 40 | 200 mm | 225 mm | 88 mm | 110 mm | 150 mm | 4 x 18 (M16) | 16 kg | |

| DN 50 | 230 mm | 230 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 19 kg | |

| DN 80 | 310 mm | 340 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 39 kg | |

| DN 100 | 350 mm | 350 mm | 158 mm | 180 mm | 220 mm | 8 x 18 (M16) | 44 g |

ANSI Standards

| Size | L2 | H | ød | øk | øD | Bolting | Weight |

|---|---|---|---|---|---|---|---|

| NPS ½" | 130 mm | 130 mm | 34,9 mm | 60,3 mm | 88,9 mm | 4 x 15.9 | 6 kg |

| NPS ¾" | 130 mm | 130 mm | 42,9 mm | 69,8 mm | 98,4 mm | 4 x 15.9 | 6 kg |

| NPS 1" | 160 mm | 185 mm | 50,8 mm | 79,4 mm | 108 mm | 4 x 15.9 | 11 kg |

| NPS 1½" | 200 mm | 225 mm | 73 mm | 98,4 mm | 127 mm | 4 x 15.9 | 16 kg |

| NPS 2" | 230 mm | 230 mm | 92,1 mm | 121 mm | 152,4 mm | 4 x 19 | 19 kg |

| NPS 3" | 310 mm | 340 mm | 127 mm | 152,4 mm | 190,5 mm | 4 x 19 | 39 kg |

| NPS 4" | 350 mm | 350 mm | 157,2 mm | 190 mm | 228,6 mm | 8 x 19 | 44 kg |

Imperium9 Materials

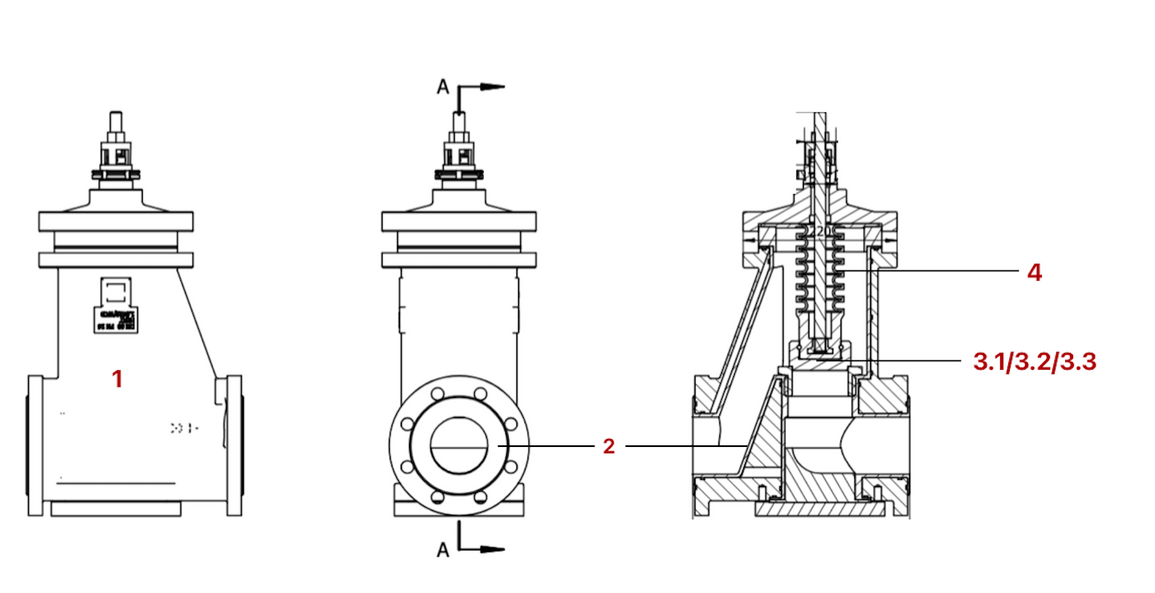

| Pos. | Item | Material |

|---|---|---|

| 1 | Body | 1.0619 or 1.4308/1.4408/1.4409 | A216/WCB,CF8/CF8M/CF3M |

| 2 | Lining | PFA Perfluoralkoxy (standard) or PFA-LantistaticF-L (on request) |

| 3.1 | Trim Variant 1 | Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow (standard)) |

| 3.2 | Trim Variant 2 | V-Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow) |

| 3.3 | Trim Variant 3 | U Plug (TFM-PTFE) | Seat (TFM-PTFE) | Bellow (PFA HD-bellow (standard)) |

| 4 | Bellow | PFA |

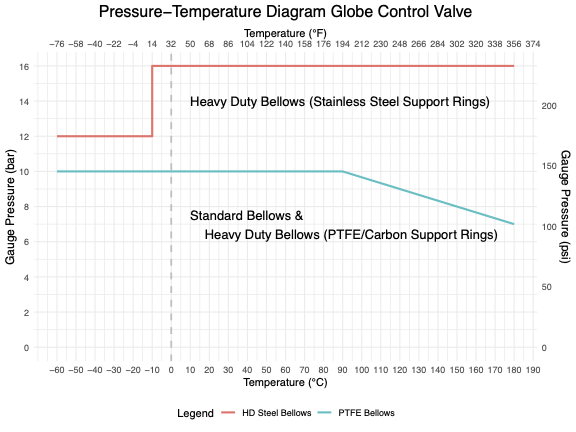

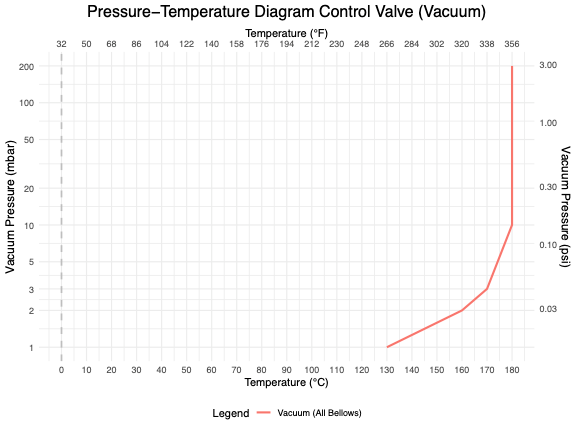

Pressure Temperature Diagram

Industry Applications

With its powerful pneumatic actuator, multi-functional digital positioner, and reliable stem seal, this valve is designed for industries such as chemical processing, biotechnology, and oil and gas, where precision control and operational safety are paramount. More general, its protective anti corrosive PFA lining makes it the perfect choice for handling hazardous or slightly solids-containing media. The adaptability of the GCV series ensures that it meets specific requirements for kvs-values, permissible leakage rates, and noise levels, making it a versatile choice for demanding applications.

Chemical & Fine Chemical Processing

Pharmaceutical & Biopharmaceutical Production

Oil & Gas Processing & Refining

Battery & Semiconductor Manufacturing

Water Treatment & H2O Generation

Food & Beverage Processing

Mining & Mineral Processing

Biodiesel & Renewable Energy Production

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.