Certifications & Quality Control

ISO 9001

Our ISO 9001 certification reflects our dedication to implementing a robust Quality Management System (QMS), which ensures we consistently deliver high-quality products. This international standard emphasizes a risk-based approach and continual improvement, guiding us to meet customer needs while enhancing operational efficiency. It’s a foundation for our commitment to excellence, enabling us to align our processes with industry-leading practices, improve customer satisfaction, and manage risks effectively.

Trusted Supplier

Our products are trusted by leading global companies in the chemical, agrochemical, and pharmaceutical sectors, such as Bayer, Mersen, Covestro, and SchuF. These partnerships are a testament to our commitment to quality and consistency. We have built long standing relationships by continuously meeting rigorous standards across various applications, proving our reliability and dedication to innovation and

customer satisfaction.

Internal Quality Control

Our internal quality control processes are aligned with stringent industry standards like DIN EN 12266-1 & 2.

We perform routine tests, including dielectric strength tests (20kV) and various hydraulic tests such as the Body Test (15 bar) and Back Seat Test (2 bar, Leakage Rate D).

Additionally, a Spark Test (15kV DC) ensures the integrity of the valve lining. These steps demonstrate our commitment to delivering products that meet the highest quality benchmarks.

Product-Specific External Certifications

Fit for Sterile Environments

GMP

Our GMP certification ensures that our products meet stringent cleanliness and quality standards. Internal surfaces are polished to Ra < 0.2μ, and external surfaces to Ra < 0.8μ, with the option of an electro-polished finish for enhanced compliance. Our design philosophy emphasizes easy flushability and minimal dead spaces, ensuring adherence to both ISO 14644-1 and GMP requirements.

Safety Integrity Level

SIL

SIL certification is a safety standard used to quantify the reliability of systems, particularly in automated and process industries. It focuses on reducing risks to a tolerable level by ensuring that equipment like ball valves and actuators meet high standards for functional safety. SIL levels range from 1 to 4, with higher numbers indicating a greater capacity for risk reduction. In industries such as oil, gas, and chemical processing, SIL certification for valves is vital, as it ensures that these components are capable of preventing failures that could lead to dangerous situations. A SIL-certified product is a mark of quality that demonstrates its capability to perform reliably in safety-critical applications

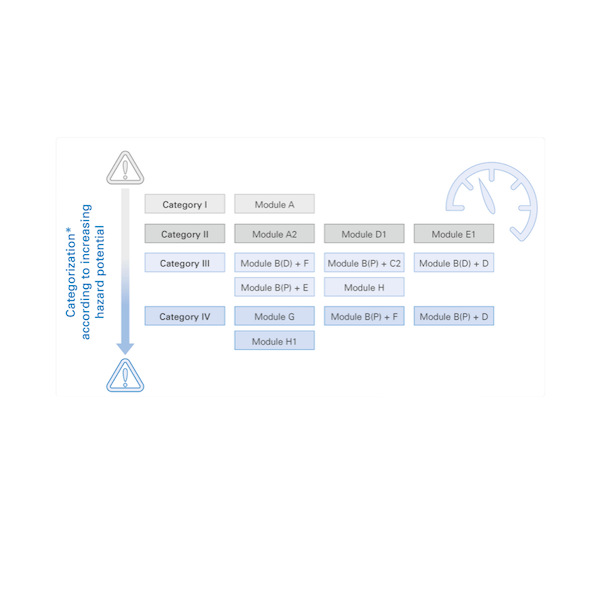

Pressure Equipment Directive

PED

PED certification is a mandatory European standard for pressure equipment, which includes valves used in systems operating at a pressure of 0.5 bar or higher. Compliance with the PED means your valves meet rigorous safety, design, and manufacturing standards set by the EU, ensuring that they can withstand high-pressure environments safely. This certification is essential not just for legal market access within the European Economic Area (EEA), but also for enhancing product quality and reducing risks related to pressure-related failures. Achieving PED certification indicates a commitment to producing reliable and safe equipment that meets the industry's best practices

Minimized Leakage Assurance

TA-Luft Certification

TA-Luft is a German air quality standard aimed at minimizing emissions and leakage from industrial components like valves. Having TA-Luft certification ensures that your ball valves are highly effective in preventing fugitive emissions, which is critical for maintaining environmental standards. This certification is crucial in industries that deal with hazardous substances, as it guarantees compliance with Germany's stringent air pollution control regulations, promoting cleaner production processes.