GFT 9

PFA Transfer Molding Meets Precision Engineering

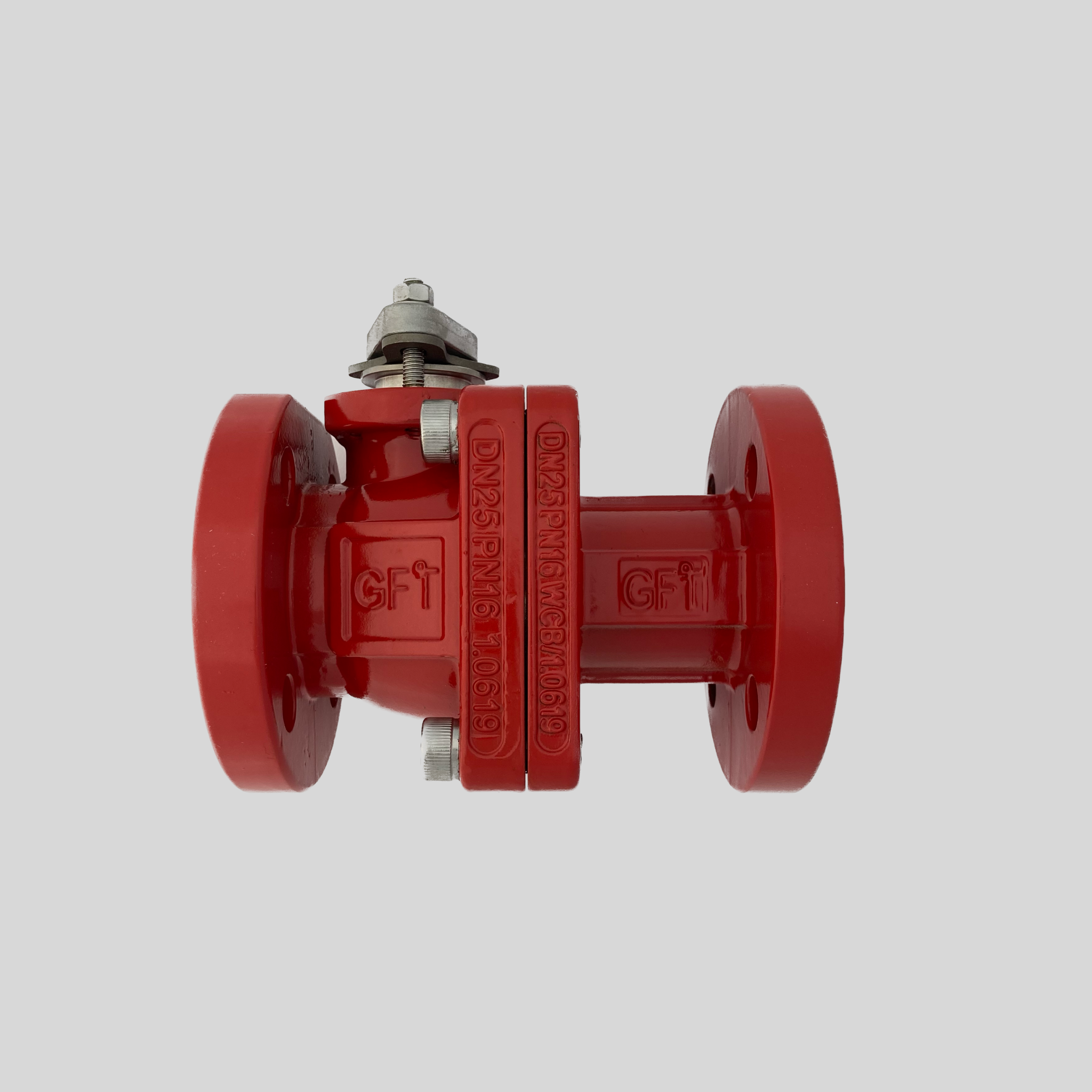

PFA Lined Ball Valve

Key Specifications

Design Norm: DIN | ANSI

Operational Characteristics: On / Off

Lining: PFA, PFA/UP, PFA/AS, PVDF, PP, UHMW-PE

Body: 1.0619 (A216 Gr. WCB), 1.4408 (CF8M)

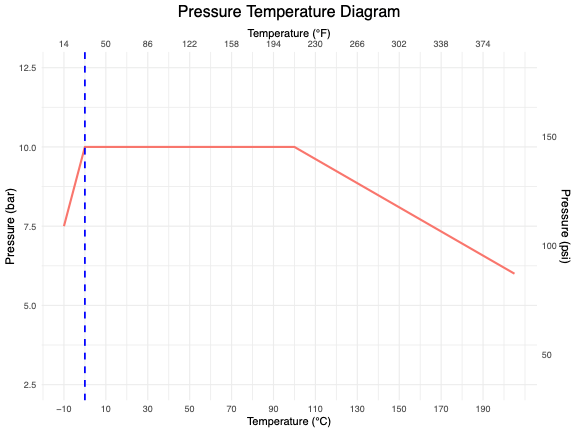

Pressure Range: up to 16 bar (see P-T Diagram)

Temperature Range: -60°C to 150°C (see P-T Diagram)

Partner with GFT9

Global Reach

Manufacturer

Dependable

Core PFA Features

Corrosion Resistance

Low Friction / Non-Stick

Electrical Insulation

Thermal Stability

बॉल_वाल्व DIN Features

Our बॉल_वाल्व DIN Certificates

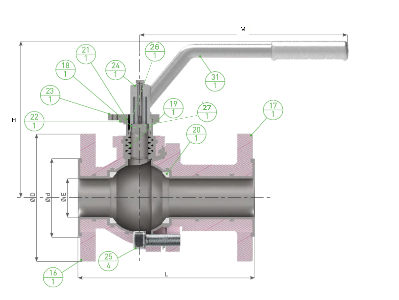

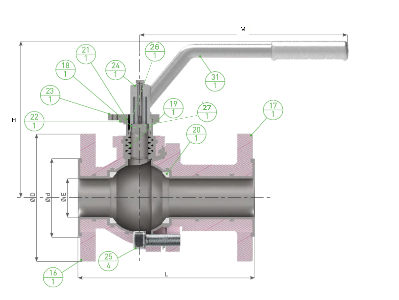

Spheron9 Measurements

DIN Standards

| Size | L | L2 | H | ød | øk | øD | Bolting | Torque | Kvs | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| DN 15 | 130 मि॰मी॰ | 58.5 मि॰मी॰ | 126 मि॰मी॰ | 45 मि॰मी॰ | 65 मि॰मी॰ | 95 मि॰मी॰ | 4 x 14 (M12) | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 180 | 8 कि॰ग्रा॰ |

| DN 20 | 150 मि॰मी॰ | 58.5 मि॰मी॰ | 126 मि॰मी॰ | 58 मि॰मी॰ | 75 मि॰मी॰ | 105 मि॰मी॰ | 4 x 14 (M12) | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 180 | |

| DN 25 | 160 मि॰मी॰ | 52 मि॰मी॰ | 126 मि॰मी॰ | 68 मि॰मी॰ | 85 मि॰मी॰ | 115 मि॰मी॰ | 4 x 14 (M12) | 12 (<3 bar), 12 (6 bar), 12 (10 bar), 12 (16 bar), 12 (max. adm. [Nm]) | 180 | 12 कि॰ग्रा॰ |

| DN 32 | 180 मि॰मी॰ | 60 मि॰मी॰ | 126 मि॰मी॰ | 78 मि॰मी॰ | 100 मि॰मी॰ | 140 मि॰मी॰ | 4 x 18 (M16) | 180 | 18 कि॰ग्रा॰ | |

| DN 40 | 200 मि॰मी॰ | 67.5 मि॰मी॰ | 200 मि॰मी॰ | 88 मि॰मी॰ | 110 मि॰मी॰ | 150 मि॰मी॰ | 4 x 18 (M16) | 20 (<3 bar), 20 (6 bar), 20 (10 bar), 25 (16 bar), 250 (max. adm. [Nm]) | 270 | 20 कि॰ग्रा॰ |

| DN 50 | 230 मि॰मी॰ | 80 मि॰मी॰ | 200 मि॰मी॰ | 102 मि॰मी॰ | 125 मि॰मी॰ | 165 मि॰मी॰ | 4 x 18 (M16) | 25 (<3 bar), 25 (6 bar), 25 (10 bar), 30 (16 bar), 361 (max. adm. [Nm]) | 270 | 25 कि॰ग्रा॰ |

| DN 65 | 290 मि॰मी॰ | 77.5 मि॰मी॰ | 220 मि॰मी॰ | 122 मि॰मी॰ | 145 मि॰मी॰ | 185 मि॰मी॰ | 4 x 18 (M16) | 380 | 50 कि॰ग्रा॰ | |

| DN 80 | 310 मि॰मी॰ | 85.5 मि॰मी॰ | 260 मि॰मी॰ | 138 मि॰मी॰ | 160 मि॰मी॰ | 200 मि॰मी॰ | 8 x 18 (M16) | 60 (<3 bar), 60 (6 bar), 60 (10 bar), 80 (16 bar), 500 (max. adm. [Nm]) | 380 | 80 कि॰ग्रा॰ |

| DN 100 | 350 मि॰मी॰ | 94 मि॰मी॰ | 270 मि॰मी॰ | 158 मि॰मी॰ | 180 मि॰मी॰ | 220 मि॰मी॰ | 8 x 18 (M16) | 80 (<3 bar), 80 (6 bar), 90 (10 bar), 170 (16 bar), 500 (max. adm. [Nm]) | 380 | 80 कि॰ग्रा॰ |

| DN 125 | 400 मि॰मी॰ | 124 मि॰मी॰ | 188 मि॰मी॰ | 210 मि॰मी॰ | 250 मि॰मी॰ | 8 x 18 (M16) | on request | on request | 85 कि॰ग्रा॰ | |

| DN 150 | 480 मि॰मी॰ | 124 मि॰मी॰ | 212 मि॰मी॰ | 240 मि॰मी॰ | 285 मि॰मी॰ | 8 x 22 (M20) | on request | on request | 250 कि॰ग्रा॰ | |

| DN 200 | 600 मि॰मी॰ | 200 मि॰मी॰ | 268 मि॰मी॰ | 295 मि॰मी॰ | 340 मि॰मी॰ | 12 x 22 (M20) | on request | on request | 600 कि॰ग्रा॰ |

ANSI Standards

| Size | L | L2 | H | ød | øk | øD | Bolting | Torque | Cv | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| NPS ½" | 108 मि॰मी॰ | 55 मि॰मी॰ | 126 मि॰मी॰ | 34.9 मि॰मी॰ | 60.3 मि॰मी॰ | 88.9 मि॰मी॰ | 4 x 15.9 | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 190 | 8 कि॰ग्रा॰ |

| NPS ¾" | 117 मि॰मी॰ | 55 मि॰मी॰ | 126 मि॰मी॰ | 42.9 मि॰मी॰ | 69.8 मि॰मी॰ | 98.4 मि॰मी॰ | 4 x 15.9 | 8 (<3 bar), 8 (6 bar), 8 (10 bar), 10 (16 bar), 80 (max. adm. [Nm]) | 190 | 12 कि॰ग्रा॰ |

| NPS 1" | 127 मि॰मी॰ | 65 मि॰मी॰ | 200 मि॰मी॰ | 50.8 मि॰मी॰ | 79.4 मि॰मी॰ | 108 मि॰मी॰ | 4 x 15.9 | 12 (<3 bar), 12 (6 bar), 12 (10 bar), 12 (16 bar), 12 (max. adm. [Nm]) | 275 | 20 कि॰ग्रा॰ |

| NPS 1½" | 165 मि॰मी॰ | 65 मि॰मी॰ | 200 मि॰मी॰ | 73 मि॰मी॰ | 98.4 मि॰मी॰ | 127 मि॰मी॰ | 4 x 15.9 | 20 (<3 bar), 20 (6 bar), 25 (10 bar), 30 (16 bar), 250 (max. adm. [Nm]) | 275 | 20 कि॰ग्रा॰ |

| NPS 2" | 178 मि॰मी॰ | 80 मि॰मी॰ | 200 मि॰मी॰ | 92.1 मि॰मी॰ | 121 मि॰मी॰ | 152.4 मि॰मी॰ | 4 x 19 | 25 (<3 bar), 25 (6 bar), 25 (10 bar), 30 (16 bar), 250 (max. adm. [Nm]) | 275 | 25 कि॰ग्रा॰ |

| NPS 3" | 203 मि॰मी॰ | 85 मि॰मी॰ | 260 मि॰मी॰ | 127 मि॰मी॰ | 152.4 मि॰मी॰ | 190.5 मि॰मी॰ | 4 x 19 | 60 (<3 bar), 60 (6 bar), 10 (10 bar), 80 (16 bar), 500 (max. adm. [Nm]) | 300 | 60 कि॰ग्रा॰ |

| NPS 4" | 229 मि॰मी॰ | 95 मि॰मी॰ | 270 मि॰मी॰ | 157.2 मि॰मी॰ | 190 मि॰मी॰ | 228.6 मि॰मी॰ | 8 x 19 | 80 (<3 bar), 80 (6 bar), 90 (10 bar), 170 (16 bar), 500 (max. adm. [Nm]) | 300 | 80 कि॰ग्रा॰ |

| NPS 6" | 394 मि॰मी॰ | 125 मि॰मी॰ | 216 मि॰मी॰ | 241 मि॰मी॰ | 279 मि॰मी॰ | 8 x 22.2 | on request | 300 | 250 कि॰ग्रा॰ | |

| NPS 8" | 457 मि॰मी॰ | 269.9 मि॰मी॰ | 330.2 मि॰मी॰ | 381 मि॰मी॰ | 12 x 25.4 | on request | on request | 600 कि॰ग्रा॰ |

Spheron9 Materials

| Pos. | Item | Material |

|---|---|---|

| 1 | Body | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 2 | Lining Body/Ball | PFA, FEP, PFA/AS, PFA/UP, PVDF, UHMW-PE* |

| 3 | Ball/Stem | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 4 | Lever | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 5 | Seat Rings | PTFE/TFM, PTFE/AS, GF PTFE, o. o. req. *2 |

| 6 | Bellow Packing | PTFE/TFM, PTFE/AS |

| 7 | Packing Gld Follow- er | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 8 | Spring Gld Follower | Spring Steel |

| 9 | Bolts and Nuts | Stainless Steel A2, A4, 5.6, o. o. req. |

Pressure Temperature Diagram

Industry Applications

As an experienced manufacturer, we know that selecting the right valve for harsh operating conditions is critical. Our PFA-lined ball valves are field-proven, operating successfully in industries where extreme corrosion resistance, reliability, and tight shut-off are essential.

Chemical Processing

Backflow control and shutoff in pipelines handling strong acids (e.g., sulfuric, hydrochloric) and caustics

Fine & Specialty Chemicals

Precise regulation of high-purity solvents and reactive intermediates to prevent contamination

Pharmaceutical & Biopharma

Maintenance of sterile, ultrapure water and buffer loops with zero particulate generation

Food & Beverage

Compliance with FDA standards for CIP and product transfer, resisting aggressive cleaning agents

Semiconductor Manufacturing

Ultra-pure chemical delivery in cleanrooms, preventing build-up and ensuring process integrity

Petrochemical & Refining

High-pressure, high-temperature control of corrosive process streams and chemical injection

Water & Wastewater Treatment

Dosing of acids, alkalis, and coagulants in water purification and desalination systems

Pulp & Paper

Flow control of bleaching agents and dyes in pulp bleaching processes

Mining & Mineral Processing

Regulation of abrasive slurries and chemical additives in ore treatment circuits

Oil & Gas Production

Service in gas-lift, methanol injection, and fracking fluid lines under extreme conditions

Interested in this product, questions or custom modifications?

Talk to our engineer or get a custom quote tailored to your application.