PFA Ball Valve (DIN-ANSI)- Stainless Steel

Order Now Or Request a Quote

Reliable & Corrosion-Resistant Flow Control

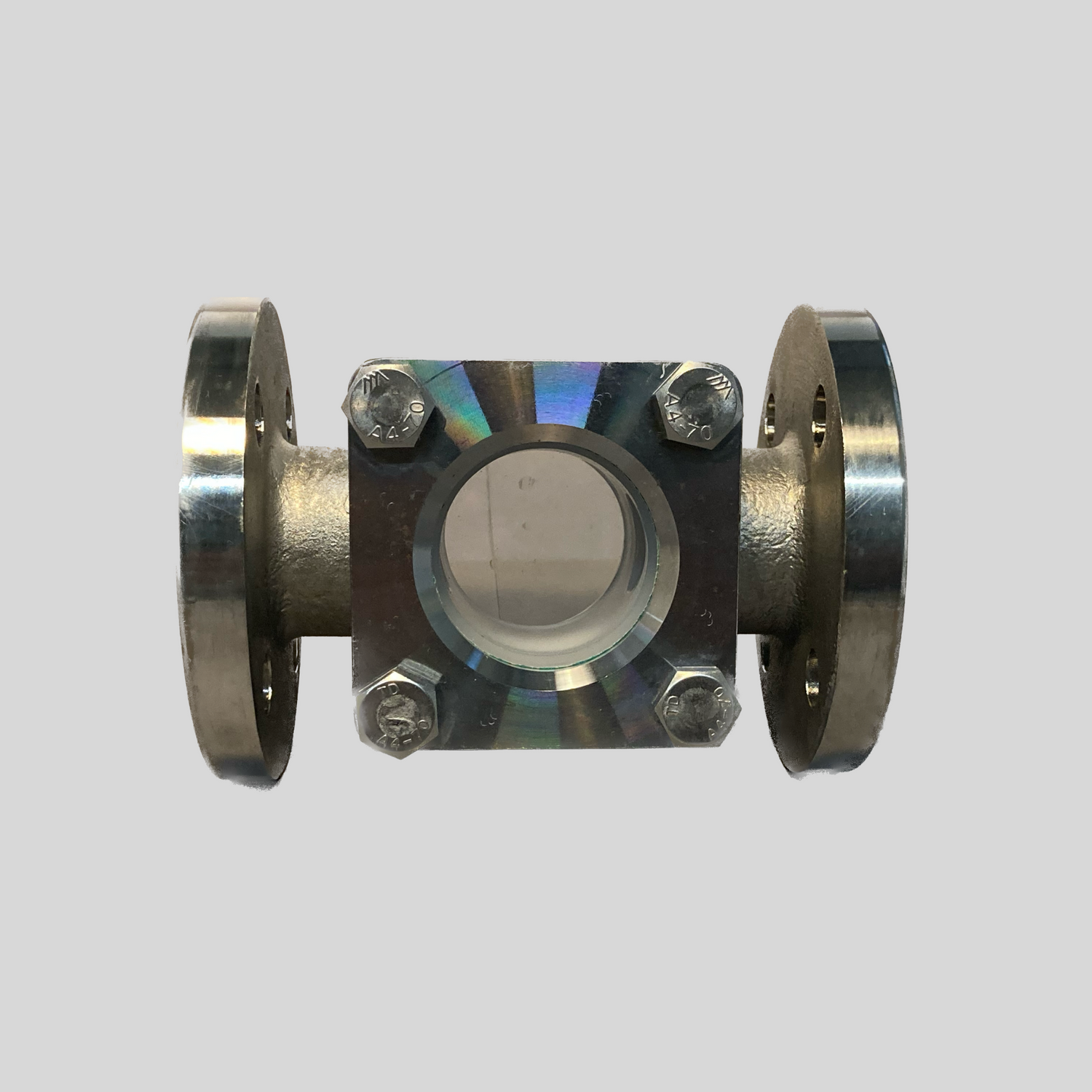

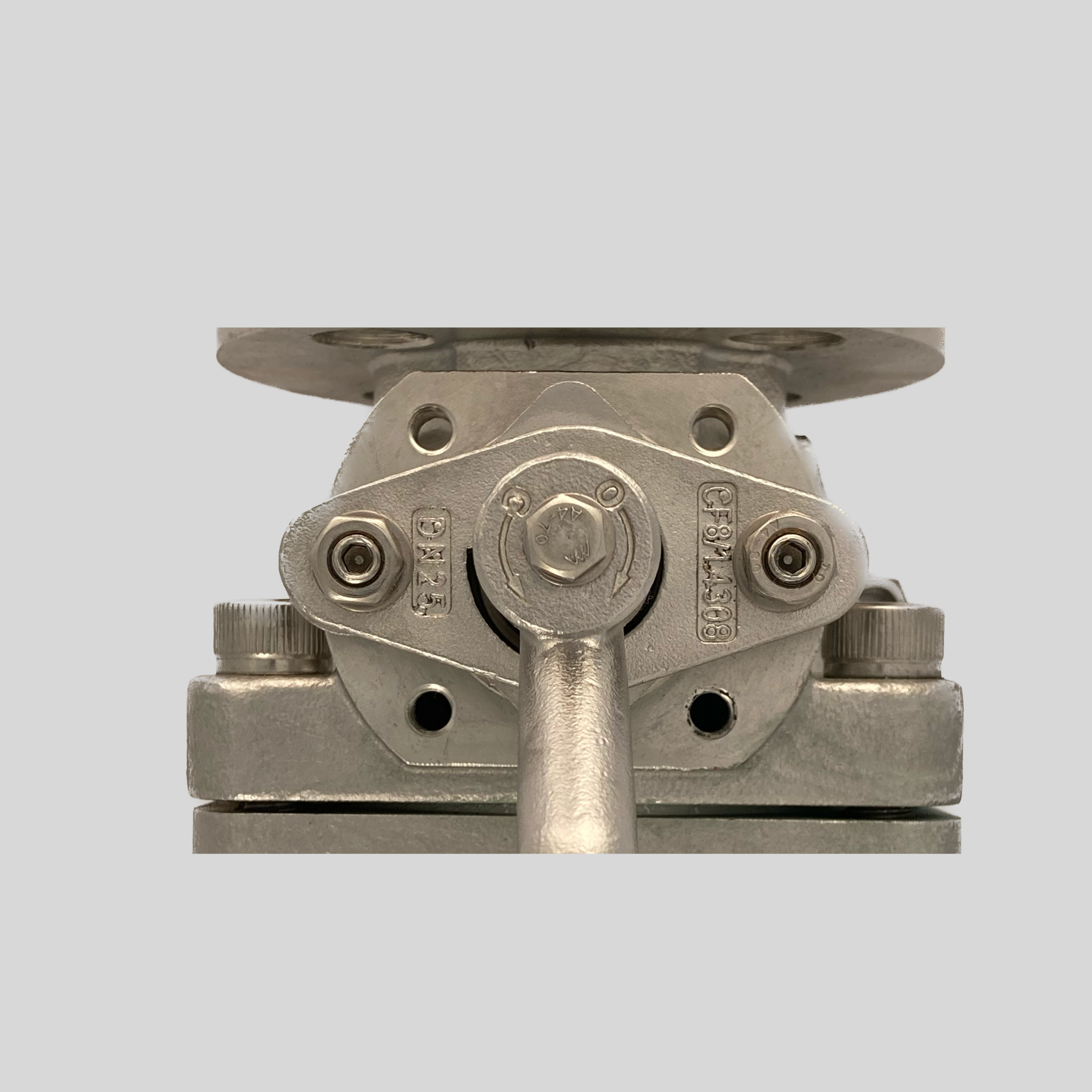

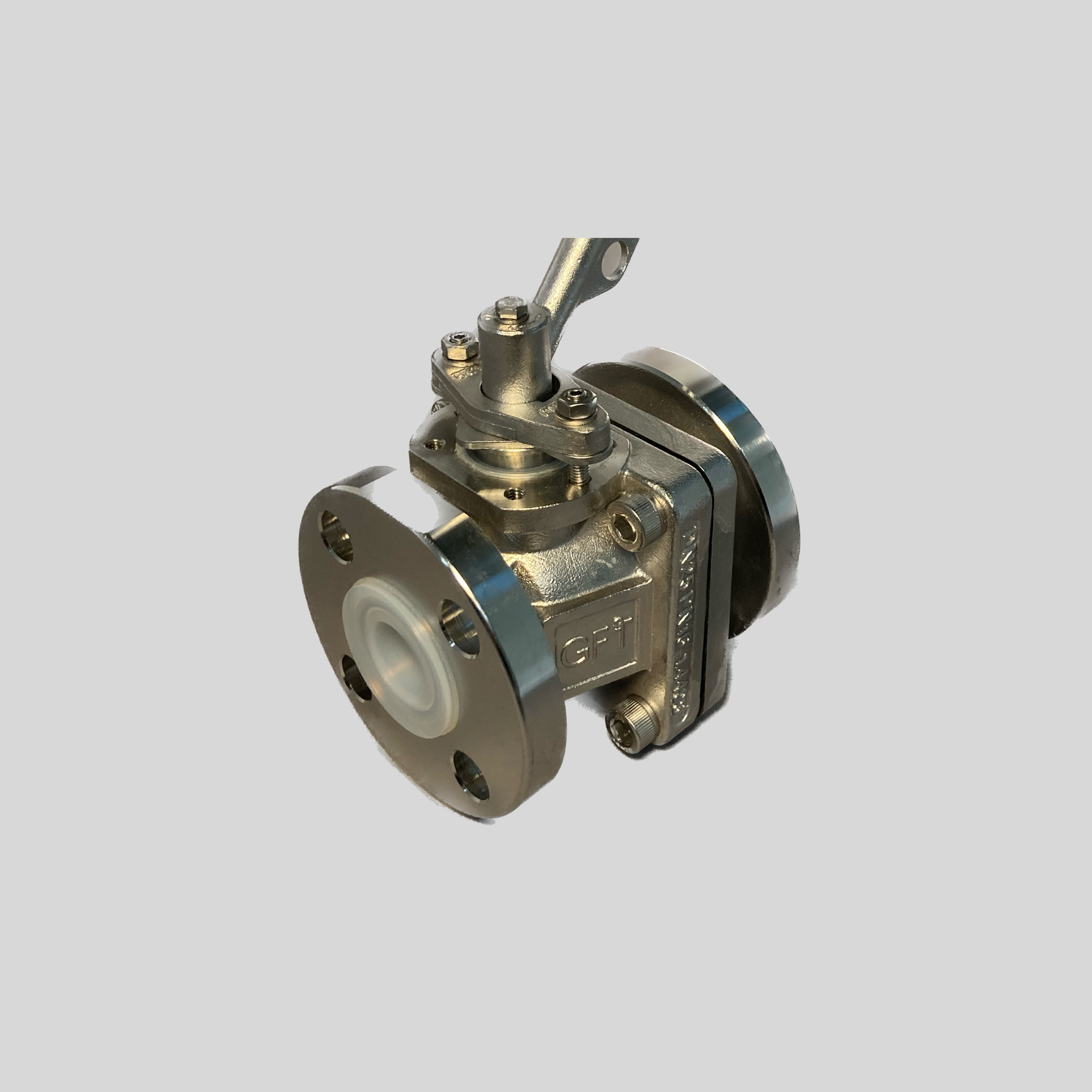

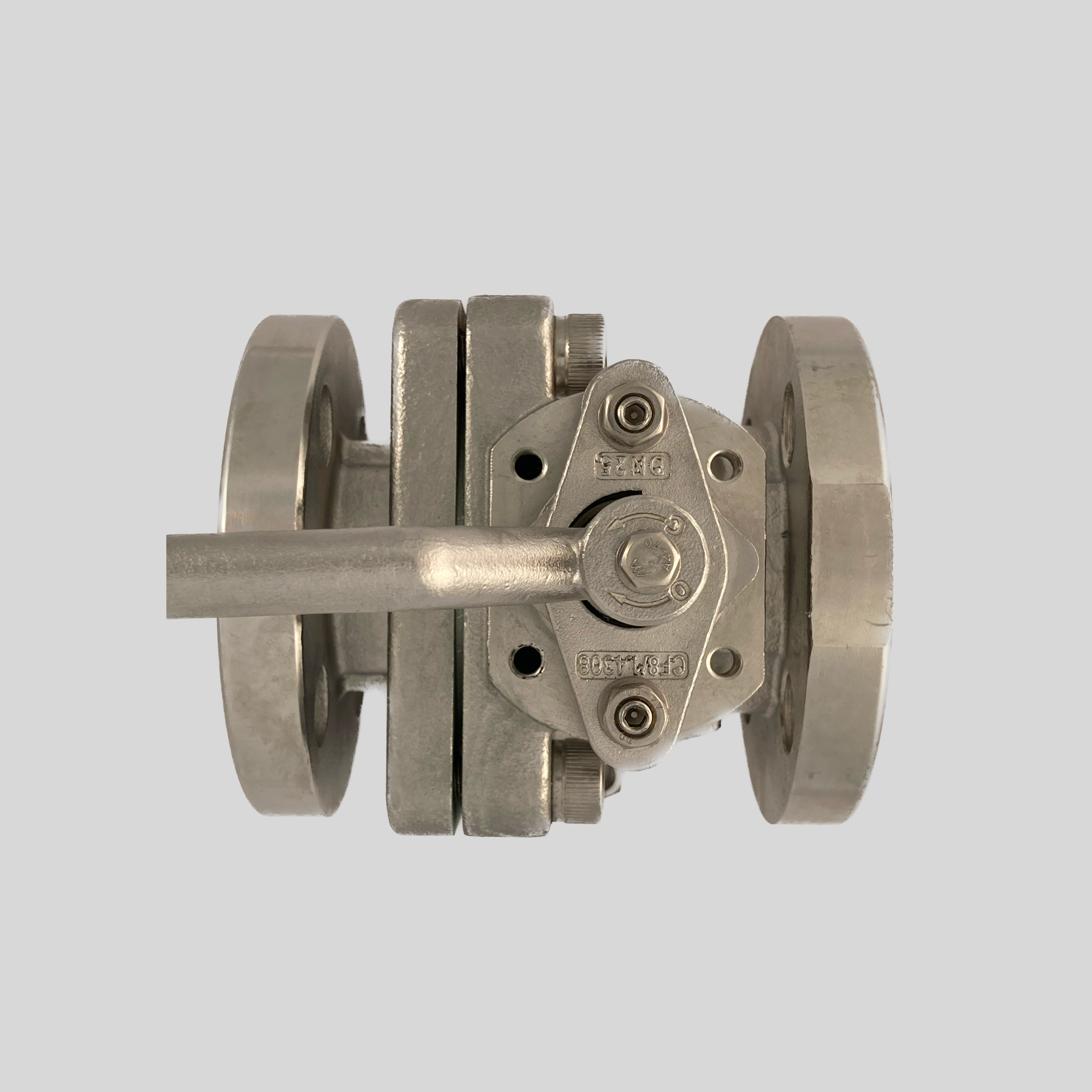

The Spheron9 PFA/Teflon Lined Ball Valve (DIN/ANSI) is tailored for high-sterile conditions where precision, durability, and cleanliness are paramount. This valve features a stainless steel body (DIN 1.4116) with a polished surface that can be enhanced with electro-polishing for even greater smoothness and sanitation. The internal virgin PFA lining ensures chemical resistance and a flushable design with no dead spaces. Its full bore allows for high Cv values while maintaining efficiency. The one-piece ball-stem design ensures reliable actuation, and the blow-out safe shaft guarantees long-term, maintenance-free performance, ideal for cleanroom settings.

Partner with GFT9

-

Global Reach

About UsOrder via our online shop and access all product documentation in various languages.

-

Manufacturer

Our CapabilitiesOffering custom modifications (lining, coating, redesign) and competitive prices.

-

-

Digital Friendly

DownloadsOrder via our online shop and access all product documentation in various languages.

Proven Performance

Industry Applications

As an experienced manufacturer, we know that selecting the right valve for harsh operating conditions is critical. Our PFA-lined ball valves are field-proven, operating successfully in industries where extreme corrosion resistance, reliability, and tight shut-off are essential.

Ball Valve Tabular Overview

| Parameter | Value |

|---|---|

| Name | Spheron9 |

| Operational Characteristics | On / Off |

| Design Norm | DIN | ANSI |

| Size | DN 15-150 | NPS ½-10 |

| Flange Dimensions | DIN 2501 (PN 16) | ASME B16.10 (Class 150-RF LP) |

| Face-Face-Dimensions | PN (EN 558-1), Series 1 | ANSI-B-16.5 |

| Actuator Connection | DIN 3337 – ISO 5211 |

| Lining Options | PFA, PFA/UP, PFA/AS, PVDF, PP, UHMW-PE |

| Body Materials | 1.0619 (A216 Gr. WCB), 1.4408 (CF8M) |

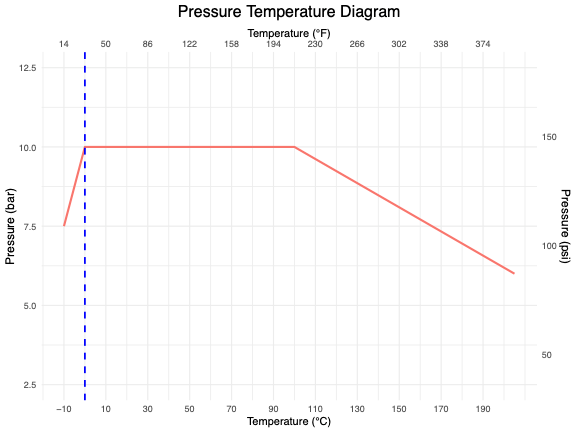

| Pressure Range | up to 16 bar (see P-T Diagram) |

| Temperature Range | -60°C to 150°C (see P-T Diagram) |

| Custom Options | Actuation, Stem Extension, Heating Jacket, Lock |

| Quality Control | Body 24 bar, Dielectric strength test 20 kV |

| Certificates | EU Pressure Equipment Directive 2014/68/EU, German Clean Air Act (TA-Luft), SIL |

Find all our Ball Valves & Request a Quote

Filter the product grid below by size, lining, and body material to find your ideal product. Once selected, add it to your cart to request a free, non-binding quote—adding to your cart does not commit you to a purchase. We’ll promptly provide pricing and estimated delivery times.

Prefer the traditional B2B approach, need clarification, or have a custom request? Feel free to reach out via email or call our sales team. Choose the method that suits you best!

-

"PFA Lined Ball Valve" DN 50

A solicitud Precio unitario / por"PFA Lined Ball Valve" DN 50

A solicitud Precio unitario / por"PFA Lined Ball Valve" DN 50

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 100

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 125

A solicitud Precio unitario / porPFA Lined Ball Valve DN 125

A solicitud Precio unitario / porPFA Lined Ball Valve DN 125

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 15

A solicitud Precio unitario / porPFA Lined Ball Valve DN 15

A solicitud Precio unitario / porPFA Lined Ball Valve DN 15

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 150

A solicitud Precio unitario / porPFA Lined Ball Valve DN 150

A solicitud Precio unitario / porPFA Lined Ball Valve DN 150

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 20

A solicitud Precio unitario / porPFA Lined Ball Valve DN 20

A solicitud Precio unitario / porPFA Lined Ball Valve DN 20

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 200

A solicitud Precio unitario / porPFA Lined Ball Valve DN 200

A solicitud Precio unitario / porPFA Lined Ball Valve DN 200

A solicitud Precio unitario / por -

PFA Lined Ball Valve DN 25

A solicitud Precio unitario / porPFA Lined Ball Valve DN 25

A solicitud Precio unitario / porPFA Lined Ball Valve DN 25

A solicitud Precio unitario / por

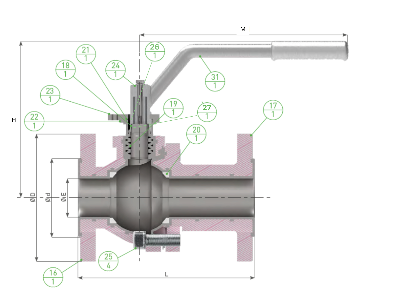

Technical Specifications

Contenido desplegable

Dimensional Measurements

| Size | L | L1 Extra | H | ød | øk | øD | Bolting | Torque | KVS | t² | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN 15 | 130 mm | 58.5 mm | 126 mm | 45 mm | 65 mm | 95 mm | 4 x 14 (M12) | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 180 | 17.5 | 8 kg |

| DN 20 | 150 mm | 58.5 mm | 126 mm | 58 mm | 75 mm | 105 mm | 4 x 14 (M12) | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 180 | 30 | |

| DN 25 | 160 mm | 52 mm | 126 mm | 68 mm | 85 mm | 115 mm | 4 x 14 (M12) | 12 (<3 bar), 12 (6 bar), 12 (10 bar), 12 (16 bar), 12 (max. adm. [Nm]) | 180 | 75 | 12 kg |

| DN 32 | 180 mm | 60 mm | 126 mm | 78 mm | 100 mm | 140 mm | 4 x 18 (M16) | 180 | 140 | 18 kg | |

| DN 40 | 200 mm | 67.5 mm | 200 mm | 88 mm | 110 mm | 150 mm | 4 x 18 (M16) | 20 (<3 bar), 20 (6 bar), 20 (10 bar), 25 (16 bar), 250 (max. adm. [Nm]) | 270 | 200 | 20 kg |

| DN 50 | 230 mm | 80 mm | 200 mm | 102 mm | 125 mm | 165 mm | 4 x 18 (M16) | 25 (<3 bar), 25 (6 bar), 25 (10 bar), 30 (16 bar), 361 (max. adm. [Nm]) | 270 | 310 | 25 kg |

| DN 65 | 290 mm | 77.5 mm | 220 mm | 122 mm | 145 mm | 185 mm | 4 x 18 (M16) | 380 | 615 | 50 kg | |

| DN 80 | 310 mm | 85.5 mm | 260 mm | 138 mm | 160 mm | 200 mm | 8 x 18 (M16) | 60 (<3 bar), 60 (6 bar), 60 (10 bar), 80 (16 bar), 500 (max. adm. [Nm]) | 380 | 800 | 80 kg |

| DN 100 | 350 mm | 94 mm | 270 mm | 158 mm | 180 mm | 220 mm | 8 x 18 (M16) | 80 (<3 bar), 80 (6 bar), 90 (10 bar), 170 (16 bar), 500 (max. adm. [Nm]) | 380 | 1250 | 80 kg |

| DN 125 | 400 mm | 124 mm | 188 mm | 210 mm | 250 mm | 8 x 18 (M16) | on request | on request | 210 | 85 kg | |

| DN 150 | 480 mm | 124 mm | 212 mm | 240 mm | 285 mm | 8 x 22 (M20) | on request | on request | 2800 | 250 kg | |

| DN 200 | 600 mm | 200 mm | 268 mm | 295 mm | 340 mm | 12 x 22 (M20) | on request | on request | 6000 | 600 kg |

| Size | L | L1 | H | ød | øk | øD | Bolting | Torque | CV | t² | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS ½" | 108 mm | 55 mm | 126 mm | 34.9 mm | 60.3 mm | 88.9 mm | 4 x 15.9 | 8 (<3 bar), 8 (6 bar), 10 (10 bar), 80 (16 bar), 80 (max. adm. [Nm]) | 190 | 17.5 | 8 kg |

| NPS ¾" | 117 mm | 55 mm | 126 mm | 42.9 mm | 69.8 mm | 98.4 mm | 4 x 15.9 | 8 (<3 bar), 8 (6 bar), 8 (10 bar), 10 (16 bar), 80 (max. adm. [Nm]) | 190 | 17.5 | 12 kg |

| NPS 1" | 127 mm | 65 mm | 200 mm | 50.8 mm | 79.4 mm | 108 mm | 4 x 15.9 | 12 (<3 bar), 12 (6 bar), 12 (10 bar), 12 (16 bar), 12 (max. adm. [Nm]) | 275 | 200 | 20 kg |

| NPS 1½" | 165 mm | 65 mm | 200 mm | 73 mm | 98.4 mm | 127 mm | 4 x 15.9 | 20 (<3 bar), 20 (6 bar), 25 (10 bar), 30 (16 bar), 250 (max. adm. [Nm]) | 275 | 200 | 20 kg |

| NPS 2" | 178 mm | 80 mm | 200 mm | 92.1 mm | 121 mm | 152.4 mm | 4 x 19 | 25 (<3 bar), 25 (6 bar), 25 (10 bar), 30 (16 bar), 250 (max. adm. [Nm]) | 275 | 310 | 25 kg |

| NPS 3" | 203 mm | 85 mm | 260 mm | 127 mm | 152.4 mm | 190.5 mm | 4 x 19 | 60 (<3 bar), 60 (6 bar), 10 (10 bar), 80 (16 bar), 500 (max. adm. [Nm]) | 300 | 800 | 60 kg |

| NPS 4" | 229 mm | 95 mm | 270 mm | 157.2 mm | 190 mm | 228.6 mm | 8 x 19 | 80 (<3 bar), 80 (6 bar), 90 (10 bar), 170 (16 bar), 500 (max. adm. [Nm]) | 300 | 1250 | 80 kg |

| NPS 6" | 394 mm | 125 mm | 216 mm | 241 mm | 279 mm | 8 x 22.2 | on request | 300 | 2800 | 250 kg | |

| NPS 8" | 457 mm | 269.9 mm | 330.2 mm | 381 mm | 12 x 25.4 | on request | on request | 5800 | 600 kg |

Materials Table & File

| Pos. | Item | Material |

|---|---|---|

| 1 | Body | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 2 | Lining Body/Ball | PFA, FEP, PFA/AS, PFA/UP, PVDF, UHMW-PE* |

| 3 | Ball/Stem | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 4 | Lever | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 5 | Seat Rings | PTFE/TFM, PTFE/AS, GF PTFE, o. o. req. *2 |

| 6 | Bellow Packing | PTFE/TFM, PTFE/AS |

| 7 | Packing Gld Follow- er | 1.0619 (A216 WCB), 1.4408 (CF-8M) |

| 8 | Spring Gld Follower | Spring Steel |

| 9 | Bolts and Nuts | Stainless Steel A2, A4, 5.6, o. o. req. |

P‑T Diagram

Pressure Temperature Diagram indicates the operating contraints of our Ball Valves in non-vaccum environments.