What is PFA? An Overview of the Polymer, its Properties and Use Cases

Share

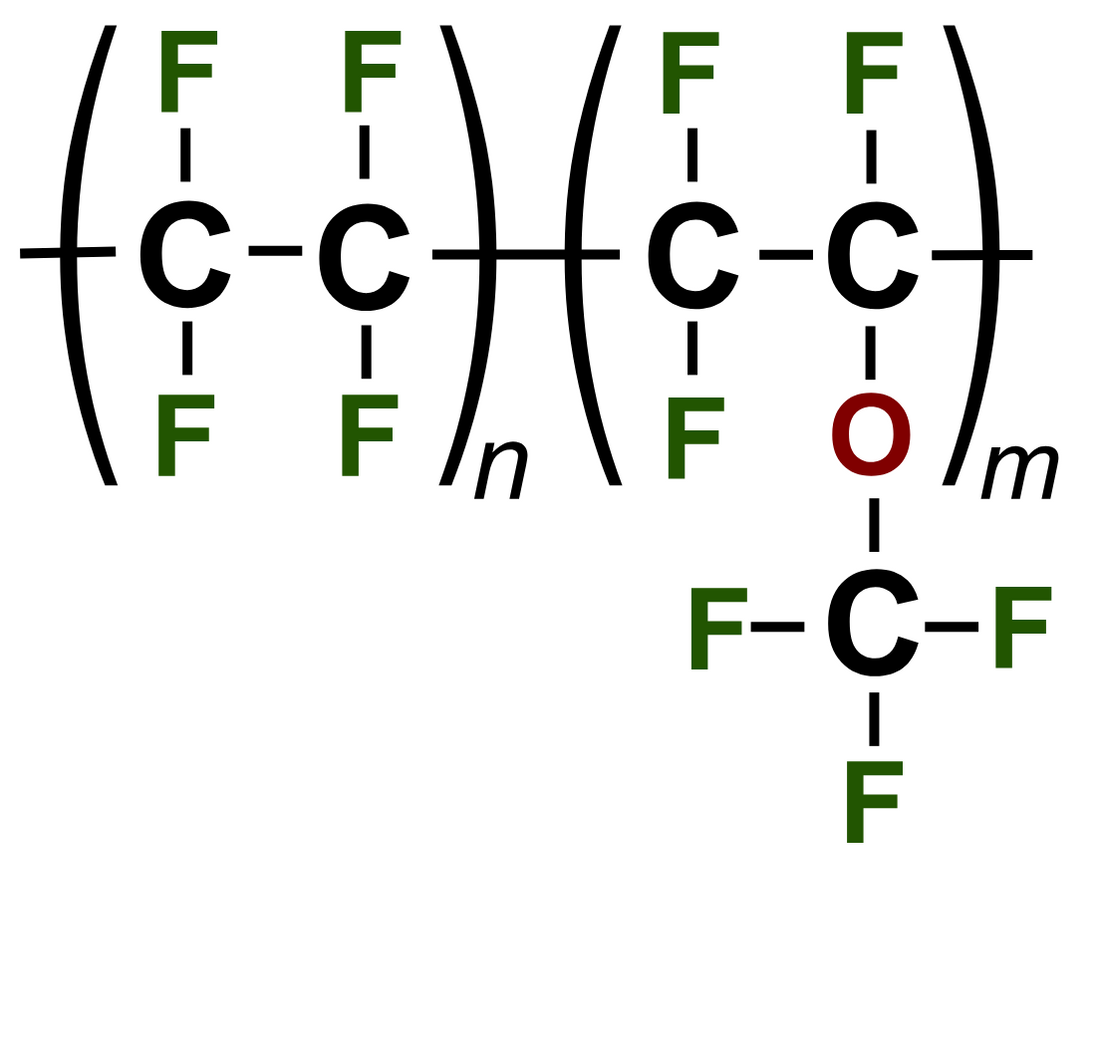

Introduction to PFA

Fluoropolymers are a group of high-performance plastics known for their nearly universal chemical resistance, excellent heat resistance, low friction coefficient, high electrical insulation, and ability to withstand high service temperatures for continuous operation. These properties make them invaluable in applications where traditional materials like stainless steel fall short in corrosion resistance. Fluoropolymers are widely used in valves, pumps, pipes, heat exchangers, and many other products.

PFA (Perfluoroalkoxy Alkane) is a member of this family, offering exceptional protection against a wide range of corrosive substances commonly found in industrial settings. These substances include acids such as sulfuric acid, strong bases like sodium hydroxide, and various chemicals used in food processing, manufacturing, healthcare, chemical industry, agriculture, mining, and more. PFA is a critical component in our products, providing reliability and safety in environments where corrosion poses a significant risk.

Key Features of PFA

1. Chemical Resistance

PFA's most notable feature is its resistance to a wide variety of chemicals, including acids, bases, solvents, and hydrocarbons. This resistance makes PFA-lined products ideal for industries dealing with aggressive chemicals, such as sulfuric acid in chemical processing or sodium hydroxide in wastewater treatment. The fluoropolymer's inertness ensures that it does not react with most substances, maintaining the purity of the fluid being handled and preventing damage to the equipment.

2. High-Temperature Performance

With a melting point of 300-310°C, PFA can withstand high temperatures that many other materials cannot, such as Polyvinylidene Fluoride (PVDF), which melts at 165-178°C. This high thermal stability makes PFA suitable for processes involving hot and corrosive fluids, like in the petrochemical industry, where hot acidic streams need to be safely transported.

3. Low Friction Coefficient

PFA's low friction coefficient ensures smooth fluid flow with minimal resistance, reducing energy consumption and wear on components. This property is particularly beneficial in dynamic applications, such as pumps and valves in pharmaceutical manufacturing, where maintaining a sterile environment is crucial. The smooth surface of PFA also helps in preventing the buildup of residues, ensuring consistent performance and easy cleaning.

4. Electrical Insulation

While electrical insulation may not be the primary concern for chemical applications, PFA's high dielectric strength (over 50 KV/mm) makes it suitable for applications where both chemical resistance and electrical insulation are needed. This property is valuable in industries where electrochemical processes are involved, such as battery production and energy generation, where PFA-lined components can prevent short circuits and chemical leaks.

Industry-Specific Applications

1. Chemical Industry

- Key Chemical: Sulfuric Acid

- Application: Handling and transportation in manufacturing processes

- Products: PFA-lined ball valves, check valves, and pipes

PFA-lined products are essential for safely handling corrosive chemicals like sulfuric acid, ensuring the longevity and reliability of equipment.

2. Pharmaceutical and Biopharma

- Key Chemical: Various solvents and acids

- Application: Sterile fluid transfer and processing

- Products: Sample valves, pumps, and fittings

The chemical resistance and purity of PFA make it ideal for maintaining sterile environments in pharmaceutical production.

3. Mining and Critical Minerals

- Key Chemical: Hydrochloric Acid

- Application: Leaching and processing of minerals

- Products: Strainers, pipes, and sight glasses

In mining, PFA-lined components withstand the harsh conditions of mineral processing, including exposure to aggressive acids used in ore leaching.

4. Food and Beverage

- Key Chemical: Cleaning agents and process fluids

- Application: Fluid handling in production lines

- Products: Strainers, valves, and hoses

PFA's non-reactive nature ensures that food and beverage products remain uncontaminated by cleaning agents and process chemicals.

5. Energy and Hydrogen Production

- Key Chemical: Hydrogen gas and corrosive byproducts

- Application: Transport and handling in energy systems

- Products: Valves, pipes, and seals

PFA's durability and chemical resistance support the safe handling of hydrogen and other energy-related chemicals.

Conclusion

PFA is a versatile and essential material for various industries, providing unparalleled chemical resistance, high-temperature performance, low friction, and excellent electrical insulation. Our PFA-lined products are designed to meet the specific needs of chemical, pharmaceutical, mining, food and beverage, energy, and other industries. They ensure safety, efficiency, and longevity in demanding applications.

For a detailed comparison of PFA's properties with other fluoropolymers and industry materials, please refer to the table below. This overview highlights PFA's advantages and helps you make informed decisions when selecting products for your specific applications.

Blog Picture Credits: By RicHard-59 - https://commons.wikimedia.org/w/index.php?curid=18465691